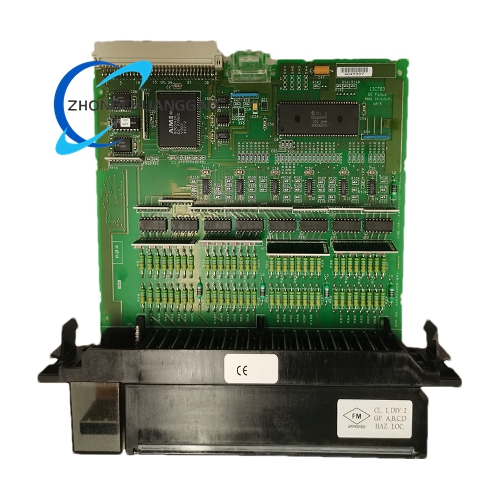

GE IC698CRE020-FF

Technical Specifications

- Processor: 1.6 GHz Intel Pentium M microprocessor

- Memory:

- 512 MB RAM (battery-backed for data retention during power loss)

- 256 MB Flash NVRAM (non-volatile storage for firmware and user programs)

- Power Requirements:

- Operating Voltage: 18–32 VDC

- Current Consumption: 1.5 A (typical)

- I/O Expansion:

- Supports up to 12 I/O modules via VME64 backplane

- Compatible with analog/digital input/output, temperature control, and motion control modules

Detailed content

- Communication Interfaces:

- 2 × 10/100 Mbps Ethernet ports (RJ-45)

- 1 × RS-485 serial port

- 1 × RS-232 serial port (for firmware updates and configuration)

- 1 × dedicated Ethernet Station Manager port

- Operating Conditions:

- Temperature: 0–60°C (operating), -40–85°C (storage)

- Humidity: 5–95% RH (non-condensing)

- Dimensions: 177 mm × 138 mm × 58 mm

- Weight: Approximately 0.7 kg

Key Functional Characteristics

- High-Speed Processing:

- The 1.6 GHz processor enables rapid execution of control algorithms, with a standard performance of 0.14 ms per 1000 Boolean contacts.

- Redundancy Support:

- HSB redundancy ensures seamless failover in critical applications, minimizing downtime.

- Flexible Memory Configuration:

- 512 MB RAM supports large-scale program execution, while 256 MB Flash NVRAM stores firmware and user data persistently.

- Multi-Protocol Communication:

- Dual Ethernet ports facilitate integration with industrial networks using protocols like Modbus/TCP, PROFIBUS DP, and DeviceNet.

- Serial ports support legacy device connectivity via Modbus RTU, SNP, and custom protocols.

- Advanced Diagnostics:

- Three LED indicators provide real-time status monitoring for CPU operation, communication activity, and fault conditions.

- Programmability:

- Supports ladder logic, function block diagram, structured text, and C programming, accommodating diverse user preferences.

- Web-Based Monitoring:

- Built-in web server allows remote system monitoring via up to 16 simultaneous web/FTP connections.

Application Scenarios

- Manufacturing Automation:

- Controls assembly lines, robotic systems, and packaging machinery in automotive and electronics manufacturing.

- Energy Management:

- Monitors and regulates power distribution systems, renewable energy installations, and oil/gas refining processes.

- Water Treatment:

- Manages pump stations, filtration systems, and chemical dosing in municipal and industrial water treatment plants.

- Transportation Systems:

- Controls traffic signals, railway signaling, and airport baggage handling systems.

- Process Control:

- Optimizes chemical processing, pharmaceutical production, and food/beverage manufacturing.

Additional Features

- ECC Memory Support:

- Error-correcting code (ECC) memory enhances data integrity, particularly in redundant configurations.

- Symbolic Variable Support:

- Auto-located symbolic variables simplify programming by eliminating manual memory addressing.

- Test Edit Mode:

- Enables real-time program modifications without halting system operation.

- Battery-Backed Calendar Clock:

- Maintains accurate system time during power cycles.