Detailed content

Technical Specifications

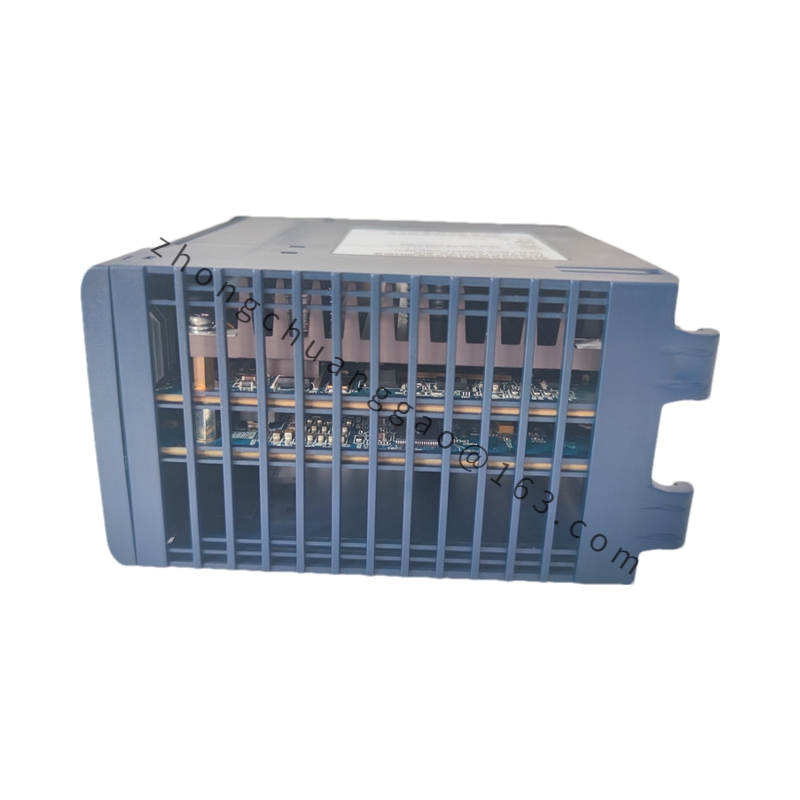

- Model: IC695CRU320-EZ

- Brand: GE (Emerson Automation Solutions)

- Series: IC695

- Type: Programmable Controller (PLC)

- CPU Speed: 800 MHz (Note: Some sources mention 1 GHz for similar models, but the specific specification for IC695CRU320-EZ is 800 MHz)

- I/O Points: 320

- Communication Interfaces: RS-232, RS-485, Ethernet

- Power Supply Voltage: 24 VDC

- Power Consumption: 50 W

- Operating Temperature: -20°C to +60°C

- Protection Rating: IP65

- Installation Method: Rail Mounting

- Dimensions: 225 x 180 x 60 mm

- Weight: 2 kg

Functional Characteristics

- High-Performance CPU: Equipped with an 800 MHz processor, providing robust processing power for complex control tasks.

- Extensive I/O Capacity: With 320 I/O points, the IC695CRU320-EZ can handle a wide range of input and output signals, making it suitable for large-scale automation projects.

- Redundant Capability: While the IC695CRU320-EZ itself is not specifically marketed as a redundant controller, it can be integrated into redundant systems using GE’s RX3i PACSystems platform, which supports hot-standby redundancy (Note: This feature is more commonly associated with the IC695CRU320 model, which specifically mentions hot-standby redundancy).

- Communication Flexibility: Offers multiple communication interfaces, including RS-232, RS-485, and Ethernet, allowing for seamless integration with other devices and systems.

- Rugged Design: With an IP65 protection rating, the IC695CRU320-EZ is designed to withstand harsh industrial environments, ensuring reliable operation in various conditions.

Application Scenarios

The GE IC695CRU320-EZ is well-suited for a wide range of industrial automation applications, including but not limited to:

- Manufacturing: In factories and manufacturing facilities, the IC695CRU320-EZ can be used to control production lines, machines, and processes, improving efficiency and reducing downtime.

- Process Industries: Suitable for applications in the chemical, oil and gas, and food processing industries, where precise control of processes is crucial.

- Infrastructure: Can be used in power generation and distribution systems, water treatment plants, and other critical infrastructure projects, ensuring reliable and efficient operation.

- Automation Systems: Part of larger automation systems, controlling multiple devices and processes, and facilitating data exchange and communication between various components.