Detailed content

Technical Specifications:

| Specification | Details |

|---|---|

| Channels | 8 single-ended analog input channels |

| Input Type | Current (configurable as 0-20 mA or 4-20 mA) |

| Resolution | 12-bit digital resolution, 5.0 μA analog resolution |

| Conversion Time | Typically 60 microseconds per channel |

| Input Range | 0.1 mA to 20 mA |

| Accuracy | ±0.1% (as per some sources) |

| Common Mode Rejection Ratio (CMRR) | >60 dB |

| Noise Immunity | >10 V RMS |

| Operating Temperature Range | -40°C to 70°C (or -25°C to 75°C, depending on source) |

| Power Supply Voltage | 24 VDC |

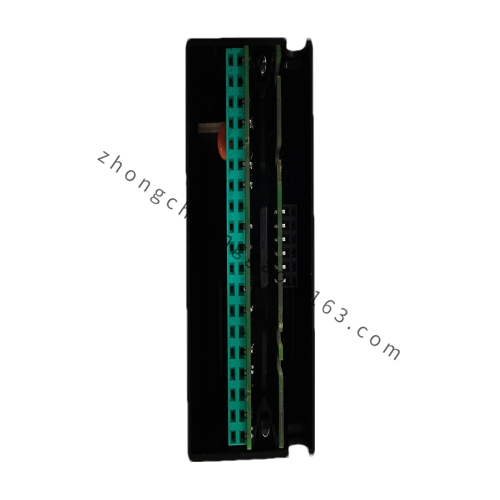

| Dimensions | 90 mm x 30 mm x 25 mm |

| Weight | 100 grams (approx.) |

| Housing Material | Aluminum alloy |

| Connection Type | Terminal block |

Functional Characteristics:

- High-Resolution Conversion: With 12-bit digital resolution and 5.0 μA analog resolution, it provides precise conversion of analog signals into digital format for processing by the host CPU.

- Configurable Input Range: The input channels can be configured to accept either 0-20 mA or 4-20 mA current signals, making it versatile for various industrial applications.

- Fast Conversion Time: Each channel has a typical conversion time of 60 microseconds, enabling real-time processing of analog data.

- Internal Protection: Features internal protection mechanisms such as open-circuit detection and over-range fault detection, ensuring reliable operation.

- Analog-to-Digital Converter (ADC): Integrated ADC circuit converts received analog signals into digital format for processing.

- Input Filtering: Equipped with a first-order RC input filter for noise reduction.

- Isolation: Provides ground and logic isolation for each channel, with rated voltages of 1500 VAC (1 minute) and 250 VAC (continuous).

Application Scenarios:

- Process Control: Used in process control systems to monitor and control parameters such as temperature, pressure, flow, and level.

- Machine Control: Integrated into machine control systems to monitor and control machine parameters like speed, torque, and position.

- Data Acquisition: Collects analog data from sensors and transducers for analysis and control purposes in various industrial settings.

- Interface with Field Devices: Connects to field signal transmitters, panel meters, data loggers, signal splitters, variable frequency drives (VFDs), and similar devices.

High-Authority Sources:

- The technical specifications and functional characteristics are compiled from various reliable sources, including product descriptions from manufacturers’ websites, automation equipment suppliers, and technical documentation.