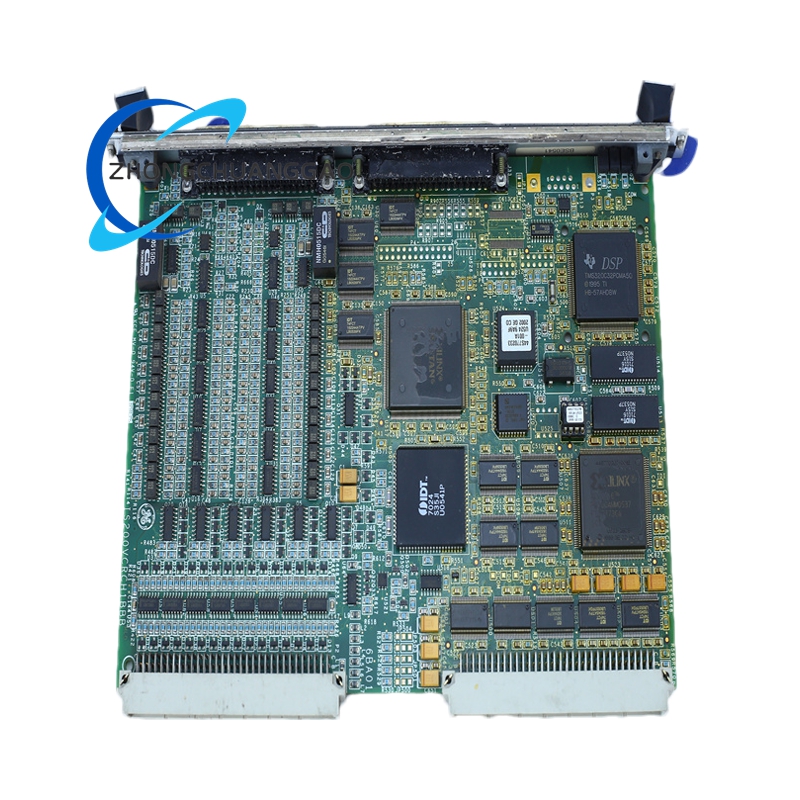

GE IC200MDL742D Analog Output Module

Technical Specifications

- Brand: GE (General Electric)

- Model: IC200MDL742D

- Type: Analog output module for PLC systems

- Output Channels: Supports multiple analog output channels (specific channel count depends on configuration, typically ranging from 2 to 8 channels).

- Output Signal Type: Voltage or current output (configurable based on application requirements).

- Voltage Output Range: 0-5V, 0-10V, ±5V, ±10V (configurable).

- Current Output Range: 0-20mA, 4-20mA (configurable).

Detailed content

- Resolution: 12-bit or 16-bit (depending on module version and configuration), ensuring high-precision data acquisition and signal conversion.

- Sampling Rate: High-speed sampling for real-time signal capture (specific rate depends on system configuration and PLC performance).

- Communication Protocols: Supports standard industrial protocols such as RS-485, RS-232, ModBUS, and Ethernet, enabling seamless integration into larger control systems.

- Power Supply: 24V DC (typical for industrial PLC modules).

- Operating Temperature: 0°C to 60°C (industrial-grade temperature range).

- Protection Rating: IP20 (designed for installation in protected control cabinets).

- Mounting: DIN rail mounting for compact and efficient installation.

Functional Features

- High-Precision Output: Provides accurate voltage or current output signals, ensuring reliable control of industrial processes.

- Multi-Channel Support: Enables simultaneous processing of multiple analog signals, reducing the need for additional modules and simplifying system architecture.

- Flexible Configuration: Supports configurable output ranges and signal types to match specific sensor and actuator requirements.

- Real-Time Monitoring: Offers high-speed sampling and data processing for accurate and timely monitoring of industrial processes.

- Diagnostic Capabilities: Includes self-test functions and fault detection to simplify maintenance and reduce downtime.

- Robust Design: Built with industrial-grade components to withstand harsh environments, including vibration, humidity, and electrical noise.

Application Scenarios

- Manufacturing: Controls precision machinery in CNC systems, robotic arms, and assembly lines, improving production efficiency and product quality.

- Energy Industry: Monitors and controls critical equipment in power generation plants, ensuring stable and efficient operation.

- Oil & Gas: Manages safety-critical processes in extraction, refining, and pipeline systems, reducing the risk of accidents and downtime.

- Water Treatment: Optimizes pump and motor operations in municipal and industrial water treatment facilities, ensuring reliable service and efficient resource utilization.

- Transportation: Supports signaling and control systems in railways and traffic management infrastructure, enhancing safety and reliability.

- Environmental Monitoring: Used in sewage treatment and air quality monitoring systems for automated data collection and analysis.