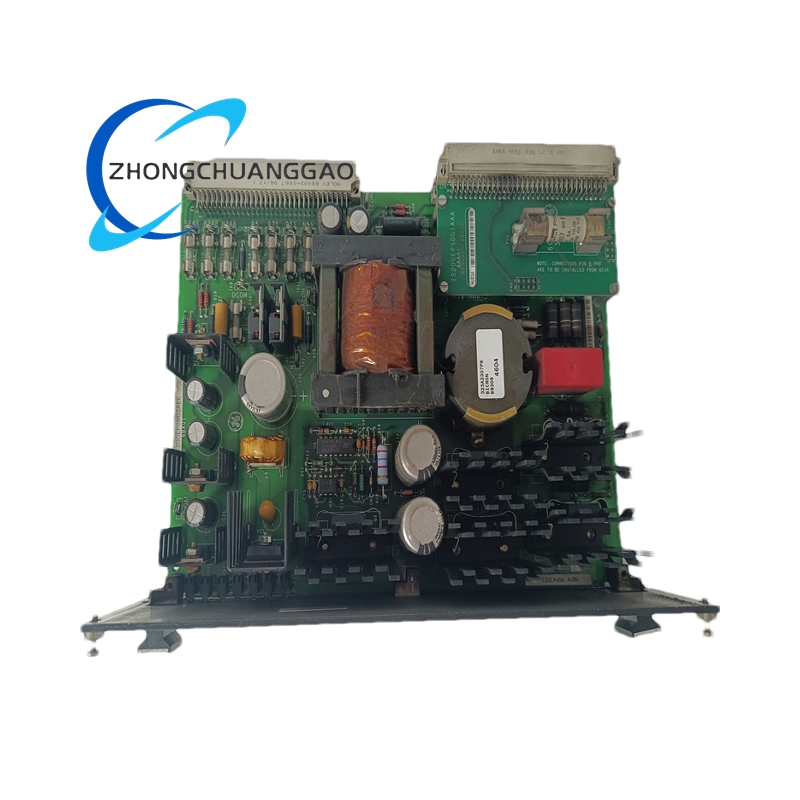

GE IC200MDL740C

- Number of Input Channels: 8 differential analog input channels

- Input Signal Types: Supports 4-20 mA DC (current) and 0-10 V DC (voltage) signals

- Input Range Accuracy:

- For 4-20 mA: ±0.1% of full scale (FS)

- For 0-10 V DC: ±0.1% of full scale (FS)

- Resolution: 16-bit ADC (Analog-to-Digital Converter)

- Sampling Rate: 10 samples per second (SPS) per channel

- Isolation: 250 V AC continuous isolation between input channels and backplane; 1500 V AC isolation for 1 minute (dielectric strength)

- Operating Temperature Range: -20°C to 60°C

- Storage Temperature Range: -40°C to 85°C

Detailed content

- Relative Humidity: 5% to 95% (non-condensing, no dew formation)

- Power Consumption: Maximum 5 V DC backplane current of 300 mA

- Dimensions: 50 mm (width) × 110 mm (height) × 66.8 mm (depth) (excluding carrier or mating connectors)

Functional Features

- High-Precision Data Acquisition: Equipped with a 16-bit ADC and ±0.1% FS accuracy, it ensures minimal measurement error when capturing analog signals, meeting the requirements of high-precision industrial processes.

- Dual Signal Compatibility: Supports both 4-20 mA current signals and 0-10 V voltage signals, eliminating the need for additional signal converters and adapting to most common industrial analog sensors.

- Channel Isolation: Each input channel features independent electrical isolation, preventing cross-interference between channels and between channels and the PLC backplane, ensuring signal stability in noisy industrial environments.

- Self-Diagnostic Function: Built-in self-diagnostic capabilities that monitor module status (such as power supply anomalies and ADC errors). Fault information is transmitted to the PLC, enabling timely maintenance and reducing system downtime.

- LED Status Indicators: Dedicated LEDs for power (PWR) and module status (STATUS) provide visual confirmation of module operation, allowing on-site personnel to quickly identify normal or fault conditions.

Application Scenarios

- Process Industry: Used in chemical, petroleum, and pharmaceutical plants to collect signals from pressure transmitters (pipe pressure), temperature sensors (reaction kettle temperature), and flow meters (fluid flow rate), supporting closed-loop control of production processes.

- Manufacturing Automation: Integrated into automated production lines (e.g., automotive assembly, electronics manufacturing) to monitor analog data such as robotic arm positioning signals, conveyor belt speed signals, and hydraulic system pressure, ensuring process consistency.

- Energy Management: Deployed in power plants, solar farms, and wind energy facilities to collect analog signals from current transformers (CT), voltage transformers (VT), and power sensors, enabling real-time monitoring of energy generation and distribution.

- Environmental Monitoring Systems: Used in wastewater treatment plants and air quality monitoring stations to capture analog data from pH sensors, dissolved oxygen sensors, and particulate matter detectors, supporting environmental compliance and process optimization.