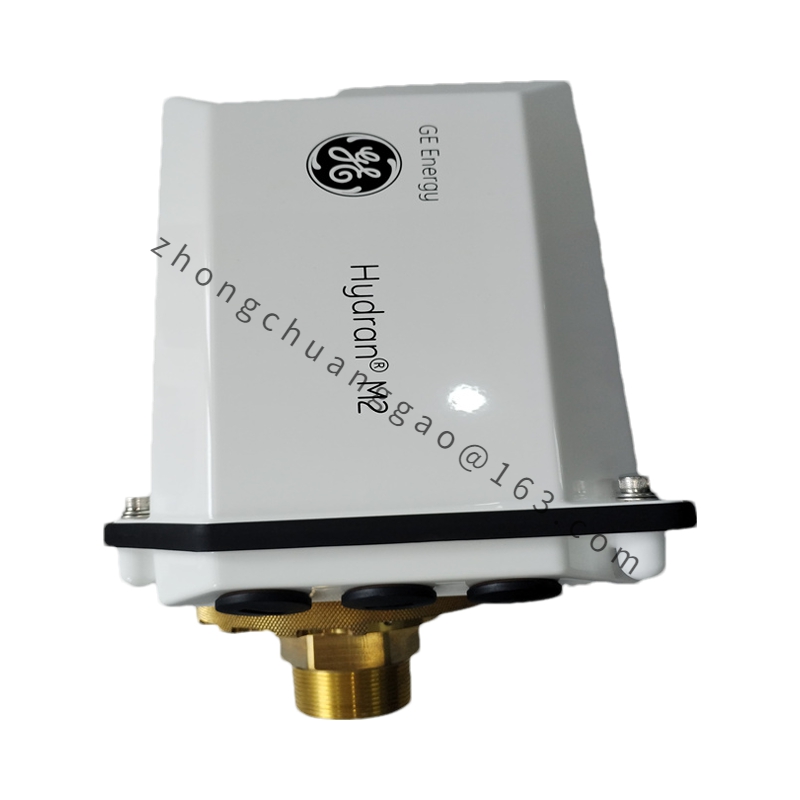

GE HYDRAN M2

Technical Specifications:

Processor: Utilizes an 80386EX processor with a speed of 25 MHz, capable of handling complex data processing tasks.

Memory: Maximum user program memory is 32K bytes, ensuring efficient storage for operational programs and data.

Operating Temperature: Designed to operate in an ambient temperature range of 0 to 60°C (32 to 140°F), suitable for various industrial environments.

Detailed content

Scan Rate: The CPU has a typical scan rate of .22 msec/K, enabling fast data acquisition and processing.

Power Requirements: Requires +5 VDC power supply, providing 670 milliamps for reliable operation.

Communication Options: Equipped with a built-in serial port supporting SNP/SNP-X slave protocols and a LAN port supporting Ethernet, FIP, Profibus, GBC, GCM, and GCM+ option modules, facilitating integration with various control systems.

Functional Characteristics:

Continuous Online Monitoring: The GE HYDRAN M2 continuously monitors dissolved gases and moisture levels in transformer oil, providing real-time information on transformer condition.

Fault Detection: Early detection of potential transformer faults by continuously measuring fault gases (such as hydrogen, carbon monoxide, acetylene, and ethylene) and moisture in the oil, minimizing the risk of unplanned outages.

Multi-Sensor Connectivity: Allows connection of additional sensors, including top and bottom tank oil temperature, transformer load, or ambient temperature, enabling comprehensive analysis by correlating sensor data with dissolved gas analysis (DGA) and moisture values.

Built-in Calculation Capabilities: Utilizes IEEE standard-based transformer mathematical models to convert raw data into useful condition information, providing a deeper understanding of the transformer’s health.

Alarm System: Features configurable alarms that alert users to abnormal levels of fault gases or moisture, with two alarm levels (Alert and Alarm) indicating increasing severity of detected issues.

High Reliability: Third-generation mature design with global installations, supporting new low-inflammable ester oils and mineral transformer insulation oils, ensuring reliable performance in various applications.

Application Scenarios:

Power Facilities: Widely used in important medium-sized transformers in power facilities, ensuring stable power supply and minimizing downtime.

Industrial Plants: Suitable for industrial plants and other facilities requiring reliable power sources, providing continuous monitoring and early fault detection to prevent unexpected shutdowns.

Critical Infrastructure: Ideal for applications where power interruptions can have significant consequences, such as hospitals, data centers, and transportation hubs.

Additional Features:

Self-Testing: Performs automatic self-tests every 15 days to detect faults (including power loss, valve closure, and sensor failures), triggering service alerts when necessary.

Display and Communication: Features a local LCD display for on-site monitoring and supports various digital communication protocols (e.g., Hydran, Modbus, DNP 3.0) and methods (e.g., RS-485, modem, Ethernet, fiber optic), allowing for seamless integration into existing systems.

Optional Outputs: Offers optional analog outputs (4-20mA) and dry contact relays for further integration with control and monitoring systems.