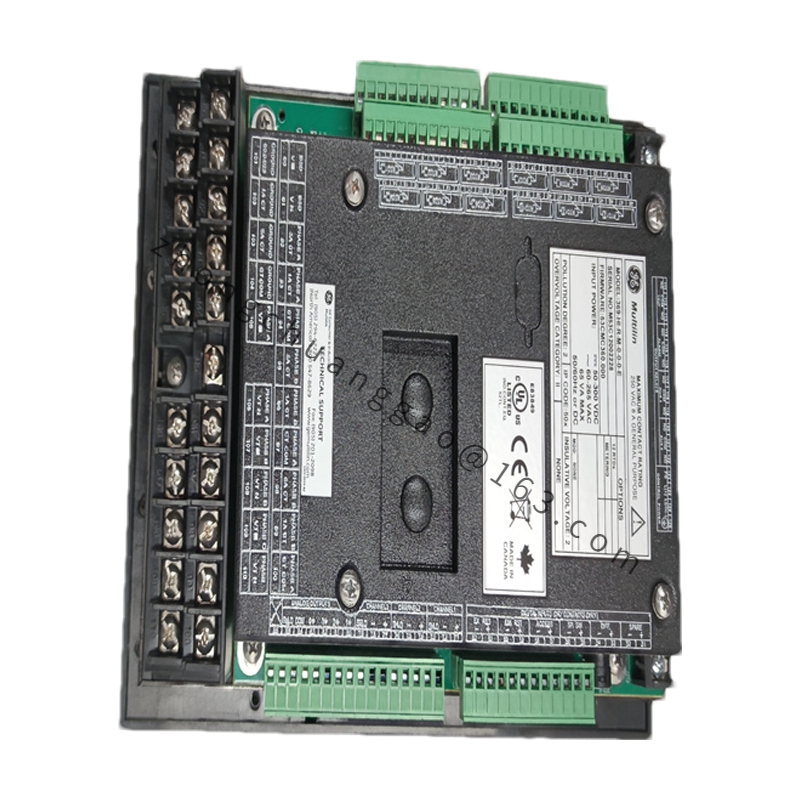

GE 369-HI-R-M-0-0-0-E

Technical Specifications:

Type: Electromagnetic Relay

Input Voltage Range: 12-48VDC

Output Voltage: 5VDC

Output Current: Max 10A

Efficiency: Greater than 90%

Size: 170mm x 105mm x 32mm

Weight: Approximately 120g

Operating Temperature: -20°C to +50°C

Storage Temperature: -40°C to +70°C

Environmental Humidity: 5% to 95% RH (non-condensing)

Processor: 32-bit RISC Processor

Detailed content

Functional Features:

Relay Control: The GE 369-HI-R-M-0-0-0-E is an electromagnetic relay that controls the on/off of the circuit through the attraction and release of contacts.

High Contact Capacity: With its large contact capacity, it can withstand heavy current loads, making it suitable for controlling the start, stop, and direction of motors.

Long Lifespan:

Mechanical Lifespan: It maintains normal operation after multiple suction and release cycles, ensuring high durability.

Electrical Lifespan: Designed for long-term continuous operation, suitable for industrial automation equipment requiring stability.

Installation: It adopts a standard DIN rail installation method, facilitating easy installation on control cabinets or operation panels.

Protection Level: With a high protection level, it is suitable for harsh working environments, offering excellent dust-proof, moisture-proof, and shockproof performance.

Additional Features: Small size, light weight, high reliability, and strong anti-interference ability.

Advanced Functions:

Overload Protection: Monitors motor current and disconnects the circuit when it exceeds a set threshold, preventing motor overload.

Temperature Monitoring: Some models may include temperature monitoring to prevent motor overheating, which could lead to damage.

Phase Sequence Protection: Ensures the correct motor phase sequence, as incorrect phasing can result in reverse rotation or unsafe conditions.

Stall Protection: Detects motor stall conditions and takes appropriate measures, such as stopping the motor, to prevent damage.

Communication Interface: Some versions may be equipped with communication interfaces for remote monitoring and control, allowing integration with other systems.

Fault Recording: Records any abnormal events during motor operation, aiding in problem diagnosis and maintenance.

Programmability: Configurable and customizable according to specific application needs.

Application Scenarios:

Power Plants: Used to monitor and protect generators, transformers, switchgear, and other electrical equipment, ensuring reliable operation and providing overload and short-circuit protection.

Substations: Found in substations to monitor and protect high-voltage and distribution equipment such as transformers, switchgear, and cables.

Transmission and Distribution Systems: Ensures safe distribution of electricity to end-users by detecting current overloads, voltage abnormalities, and other power system issues.

Industrial Facilities: Protects critical production equipment from damage or downtime, maintaining process stability and continuity.