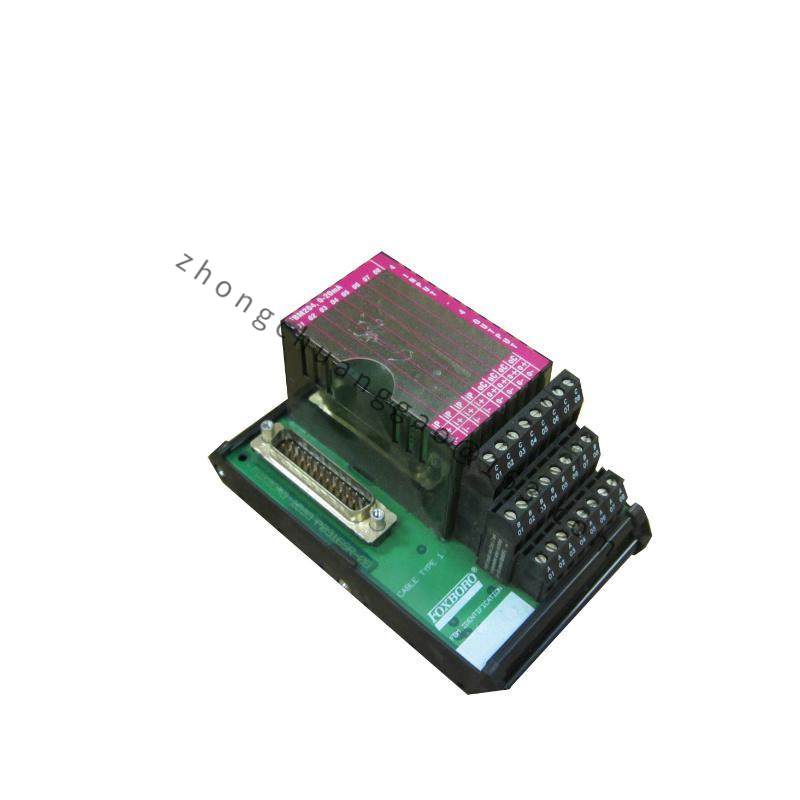

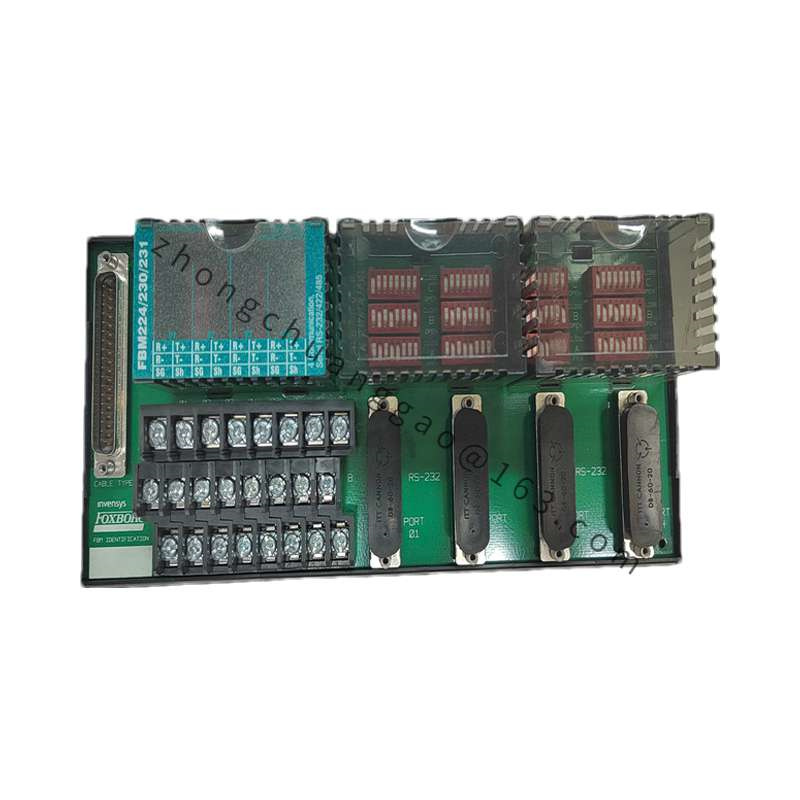

FOXBORO RH924WA Fieldbus Controller Module

- Electrical & Optical Parameters:

- Power Source: Powered directly by the FCP280 baseplate (no external power required).

- Connector Types:

- Adapter End: LC duplex connectors.

- Switch End: MT-RJ connectors.

- Cable Specifications:

- Material: Multimode fiber (MMF) 62.5/125 µm plenum-rated.

- Length: Up to 50 meters (Schneider-supplied); extendable to 2 km (user-supplied).

- Data Transfer Rate: 100 Mbps Ethernet.

Detailed content

- Environmental Ratings:

- Operating Temperature: -20°C to +60°C (-4°F to 140°F).

- Storage Temperature: -40°C to +85°C (-40°F to 185°F).

- Humidity Tolerance: 5–95% (non-condensing).

- Vibration Resistance: 0.5g (5–500 Hz).

- Protection Class: IP54 (standard); suitable for Class G3 harsh environments.

- Compliance Certifications:

- CE Marking (EMC Directive 2014/30/EU).

- UL Listed for Class I, Groups A-D; Division 2 hazardous locations.

Functional Features

- Seamless Network Integration:

- Bridges the FCP280 Field Control Processor to Ethernet switches within the Control Network, enabling real-time data exchange for Distributed Control Systems (DCS).

- Fault-Tolerant Operation:

- Supports redundant network topologies to ensure continuous operation during fiber/switch failures.

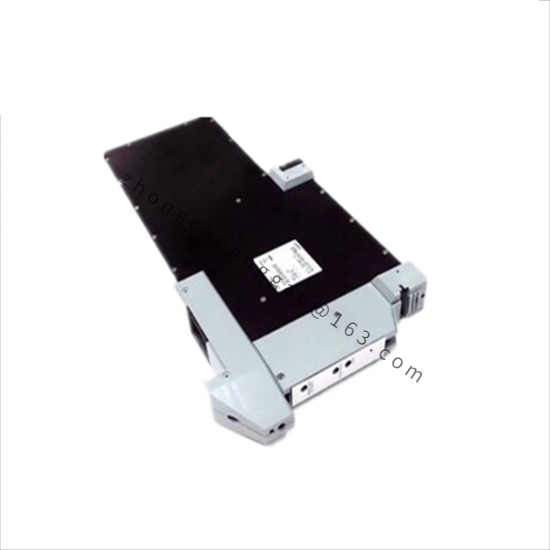

- Industrial Durability:

- Designed for harsh environments (e.g., chemical plants, oil refineries) with plenum-rated fiber and robust connectors.

- Plug-and-Play Deployment:

- Pre-terminated cables and tool-free connectors simplify installation.

- Diagnostic Readiness:

- Compatible with Foxboro’s diagnostic tools for real-time network health monitoring.

- Compatible with Foxboro’s diagnostic tools for real-time network health monitoring.

Application Scenarios

- Industrial Process Control:

- Oil & Gas: Integrates with Foxboro I/A Series DCS to monitor pipeline pressure valves and refinery flow control.

- Chemical Processing: Ensures reliable communication for reactor temperature/pressure management.

- Power Generation:

- Connects turbine control systems (e.g., GE Mark VIe) to DCS networks for load balancing.

- Critical Infrastructure:

- Deployed in water treatment plants for pump station synchronization and failure detection.

Compatible Systems

- Hardware Integration:

- Primary Controller: Foxboro FCP280 Field Control Processor.

- Network Switches: EcoStruxure Foxboro-compatible Ethernet switches.

- Software Ecosystem:

- Foxboro Control Core Services for configuration and diagnostics.

Installation & Maintenance

- Deployment Guidelines:

- Fiber Handling: Minimum bend radius >10× cable diameter; avoid sharp bends.

- Environmental Limits: Operate within specified temperature/humidity ranges.

- Preventive Maintenance:

- Clean LC/MT-RJ connectors biannually using approved fiber optic cleaning kits.

- Verify signal integrity via network diagnostics quarterly.

- Troubleshooting:

- Link Failure: Inspect connectors for contamination or physical damage.

- Intermittent Connectivity: Check cable length compliance (≤2 km).

Certifications & Support

- Warranty: Manufacturer warranty (duration varies by supplier).

- Global Support: Technical assistance via Schneider Electric-certified engineers.