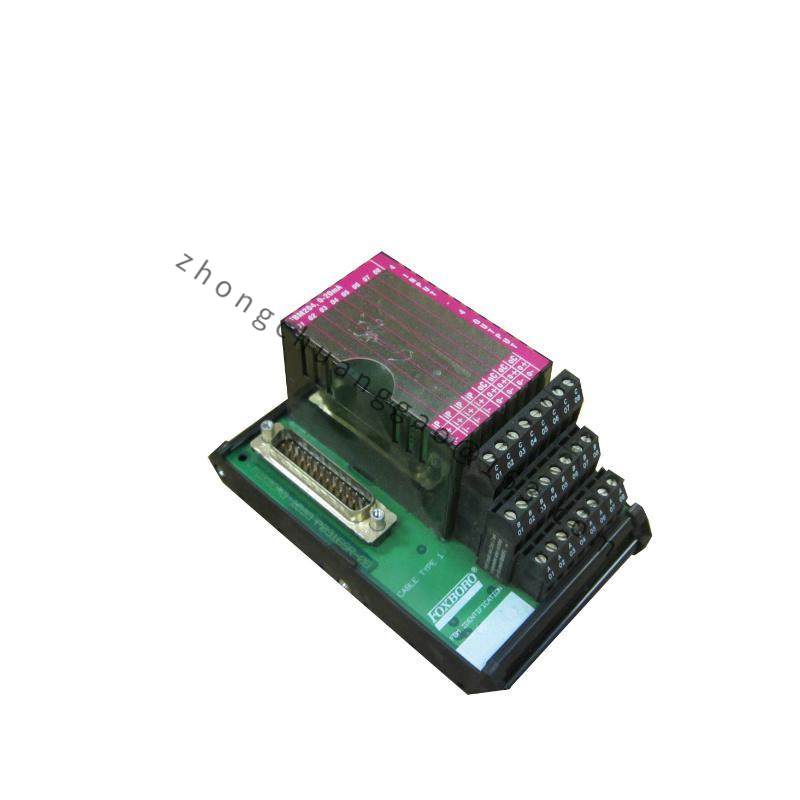

FOXBORO P0973JX

Technical Specifications

-

- Model Number: P0973JX

- Brand: FOXBORO (now part of Schneider Electric)

- Series: I/A Series

- Function Type: Communication Interface Module

- Mounting Type: Rack-mounted, compatible with I/A Series chassis

- Backplane Interface: Connects via the Universal Input/Output (UIO) bus

- Communication Capabilities: Supports high-speed serial communication protocols used in industrial automation

- Port Configuration: Dual configurable serial ports (RS-232/RS-485)

Detailed content

- Baud Rate: Configurable up to 115.2 kbps

- Data Format: Supports 7 or 8 data bits, 1 or 2 stop bits, odd/even/no parity

- Electrical Isolation: Optically isolated ports to protect against ground loops and electrical noise

- Operating Temperature: 0°C to 60°C (32°F to 140°F)

- Storage Temperature: –25°C to 70°C (–13°F to 158°F)

- Humidity Range: 5% to 95% relative humidity, non-condensing

- Power Supply: Derived from the chassis backplane

- Status Indicators: LED indicators for power, transmit, receive, and fault status

Key Features

- Robust Communication: Provides reliable serial data transmission for connecting third-party devices such as meters, drives, and analyzers

- Protocol Flexibility: Supports a wide range of industry-standard serial protocols including Modbus RTU, allowing integration with diverse equipment

- Electrical Isolation: Ensures signal integrity and system protection in electrically noisy industrial environments

- Hot-Swappable Design: Allows replacement or maintenance without shutting down the entire system

- Diagnostics and Monitoring: Built-in self-test and status reporting for easy troubleshooting and system health assessment

- Scalability: Designed to work within large-scale control systems, supporting expansion and integration with other I/A Series modules

- High Availability: Supports redundant configurations to maintain communication integrity during system faults

Applications

- Process Control Systems: Integrates field devices into the DCS for centralized monitoring and control

- Power Generation: Connects turbine controls, protection relays, and auxiliary systems

- Oil and Gas Facilities: Links flow computers, gas detectors, and remote terminal units (RTUs) to the central control system

- Water and Wastewater Plants: Interfaces with pump controllers, SCADA telemetry devices, and chemical feed systems

- Manufacturing and Production Lines: Enables communication between PLCs, HMIs, and specialized machinery

- Chemical and Pharmaceutical Processing: Ensures accurate data collection from analytical instruments and batch controllers