FOXBORO H92904CC0500 Multi-Function Industrial Module

- Technical Specifications

- Operating Temperature: -20°C to +60°C.

- Relative Humidity: 5% – 95% RH.

- Protection Level: IP20.

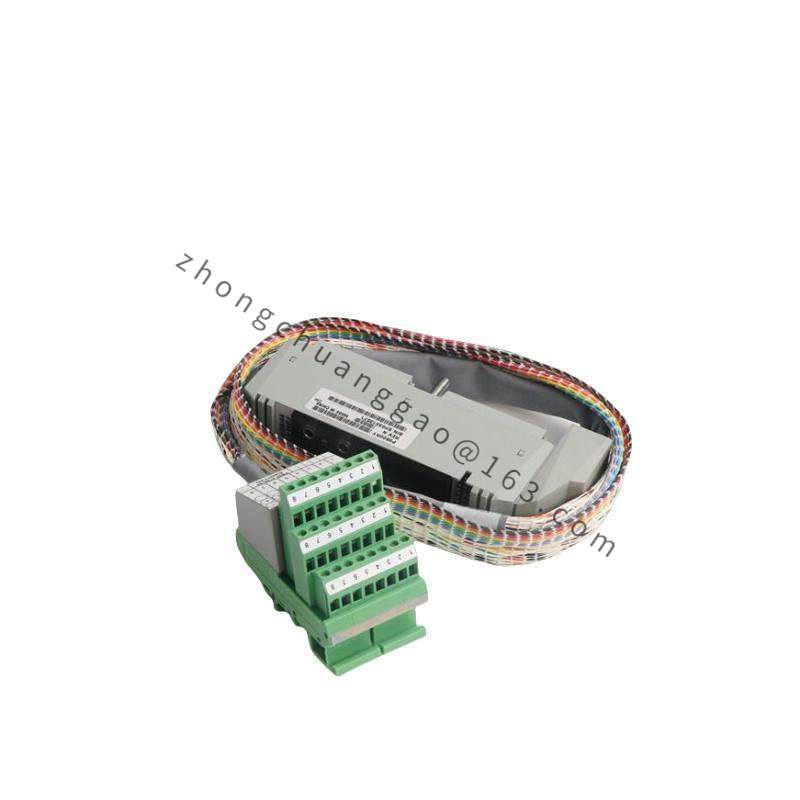

- Installation Method: DIN rail mounting, panel mounting, etc.

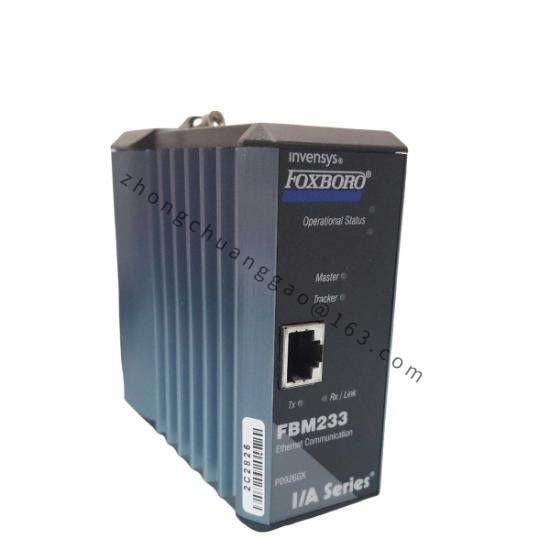

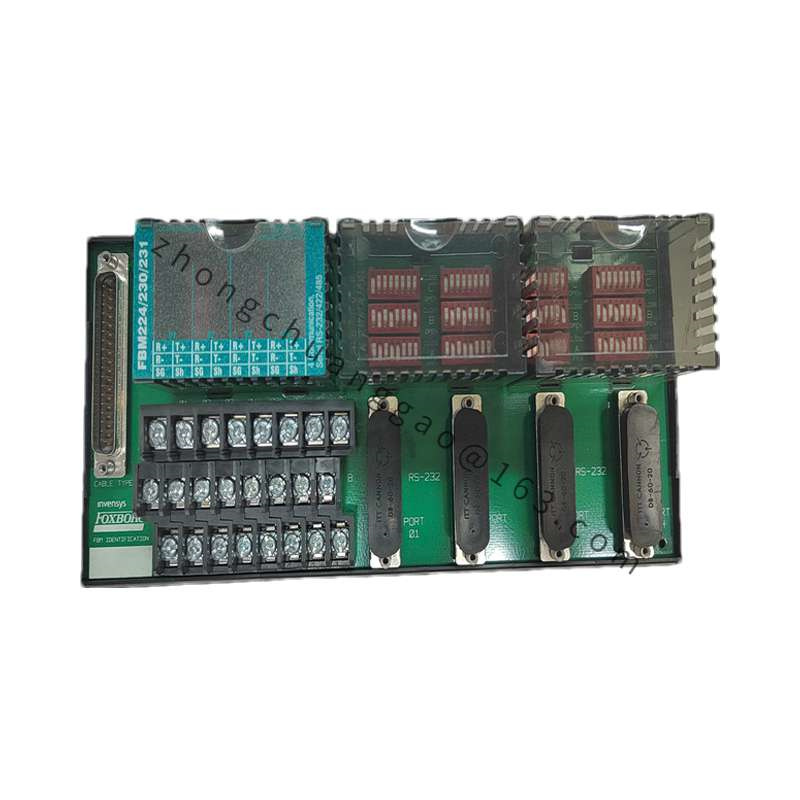

- Communication Interface: Ethernet, RS – 232, RS – 485, etc.

Detailed content

- Function Features

- Powerful Processing Capacity: It is a high – performance and reliable computer, which can handle complex control algorithms and communicate with other industrial devices.

- Protocol Compatibility: It supports a variety of industrial communication protocols, such as HART and MODBUS, which is convenient for connecting to different field devices and systems.

- High – efficiency Power Conversion: The input voltage range is 12 – 48VDC, the standard output voltage is 5VDC, the maximum output current can reach 10A, and the conversion efficiency is greater than 90%, with high – efficiency energy utilization.

- Compact Design: The size is about 170mm x 105mm x 32mm, and the weight is about 120g, which is convenient for installation and saves space.

- Application Scenarios

- Chemical Industry: It is used to monitor and control the pressure of pipelines, containers or reactors in chemical processes to ensure the safety and stability of the production process.

- Petroleum and Natural Gas Industry: It is applied to the pressure monitoring of oil wells, pipelines and storage tanks to ensure the stable operation of the production process.

- Energy Production: In power plants, it is used to monitor the pressure of steam, gas or liquid to maintain the normal operation of power – generation equipment.

- Pharmaceutical Industry: It is used to monitor the pressure of reactors, pipelines or equipment in the pharmaceutical process to ensure product quality.

- Food and Beverage Industry: In the processing and packaging process, it is used to monitor the pressure of compressed air, liquid or gas to ensure the hygiene and efficiency of the production process.

- Water Treatment: It is used to monitor the pressure of water pipelines, water pumps and water tanks to maintain the stability of the water – treatment process.

- Manufacturing Industry: In various manufacturing processes, it is used to monitor the pressure of liquids or gases to realize process control and automation.