FOXBORO FCP280 RH924YA Field Control Processor

Technical Specifications

- Hardware Architecture:

- Processor: PowerPC 604e at 1.2 GHz.

- Memory: 512 MB SDRAM + 2 GB Flash storage.

- I/O Capacity: Supports up to 128 Fieldbus Modules, including combinations of 100/200 series FBMs.

- FBM Limits: Maximum 64 × 100-series FBMs per bus.

- Power Supply: 24 V DC ±10%.

- Power Consumption: 10 W.

Detailed content

- Physical & Environmental:

- Dimensions: 147 mm length × 51.8 mm width × 116 mm height.

- Weight: 0.8 kg module, 2.0 kg shipping weight.

- Operating Temperature: -40°C to +70°C.

- Protection Rating: IP54 dust/moisture-resistant; certified for G3 harsh industrial environments.

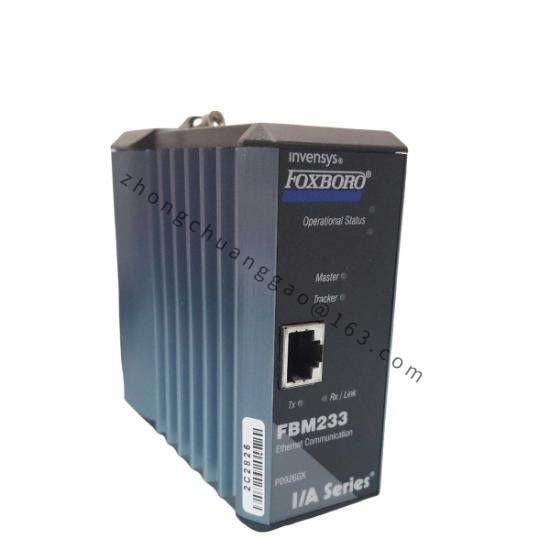

- Communication Interfaces:

- Control Network: 100 Mbps Ethernet via fiber optic or copper cable.

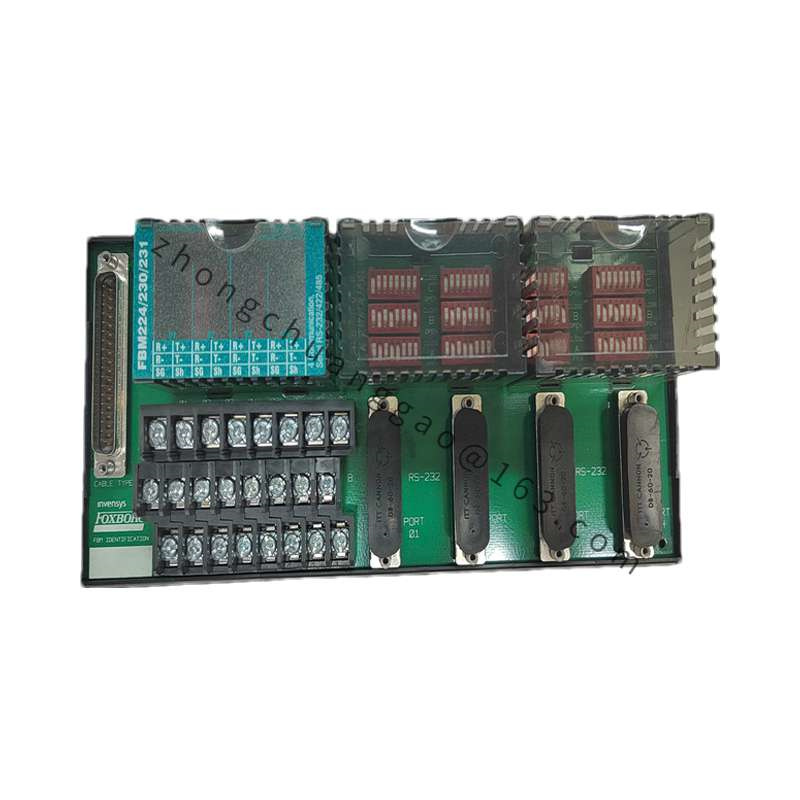

- Fieldbus Protocols: HDLC at 2 Mbps for 200-series FBMs, 268 kbps for 100-series FBMs.

- Ports: Dedicated RJ-45/PIO channels with time-synchronization strobe inputs.

Functional Features

- Fault Tolerance & Reliability:

- Dual-Module Redundancy: Active/backup modules with automatic failover.

- Self-Hosting Mode: Autonomous operation without host workstations.

- Advanced Control Capabilities:

- Real-Time Processing: Executes PID control, ladder logic, sequential control, and batch processing.

- High-Speed Functions: Supports motor-driven actuator control and distributed PID algorithms.

- Maintenance & Diagnostics:

- Online Image Upgrade: Firmware updates without process interruption.

- Front-Panel LCD: Displays system status, error codes, and network health.

- Overload Protection: Alerts during performance saturation.

- Security & Compliance:

- Encrypted Firmware: Hardware-level security against unauthorized access.

- Certifications: CE, ATEX, ISA EDSA cybersecurity.

Application Scenarios

- Process Industries:

- Oil & Gas: Controls refinery valves, pipelines, and wellhead operations.

- Chemical Plants: Manages reactor interlocks and batch processes.

- Energy Infrastructure:

- Power Generation: Integrates with turbine systems for grid stabilization.

- Water Treatment: Monitors pump stations via Modbus RTU.

- Manufacturing:

- Pharmaceuticals: Precision control for drug synthesis.

- Food & Beverage: Regulates pasteurization and filling lines.

Installation & Maintenance

- Deployment:

- DIN rail or panel mounting with ≥50 mm clearance.

- Segregate power/Ethernet lines to minimize EMI.

- Preventive Maintenance:

- Biannual fiber-optic port cleaning and firmware verification.

- Annual load testing for FBM chains.

- Troubleshooting:

- Boot Failure: Check 24V DC stability.

- Data Latency: Verify fieldbus baud rates.

Compatibility & Ecosystem

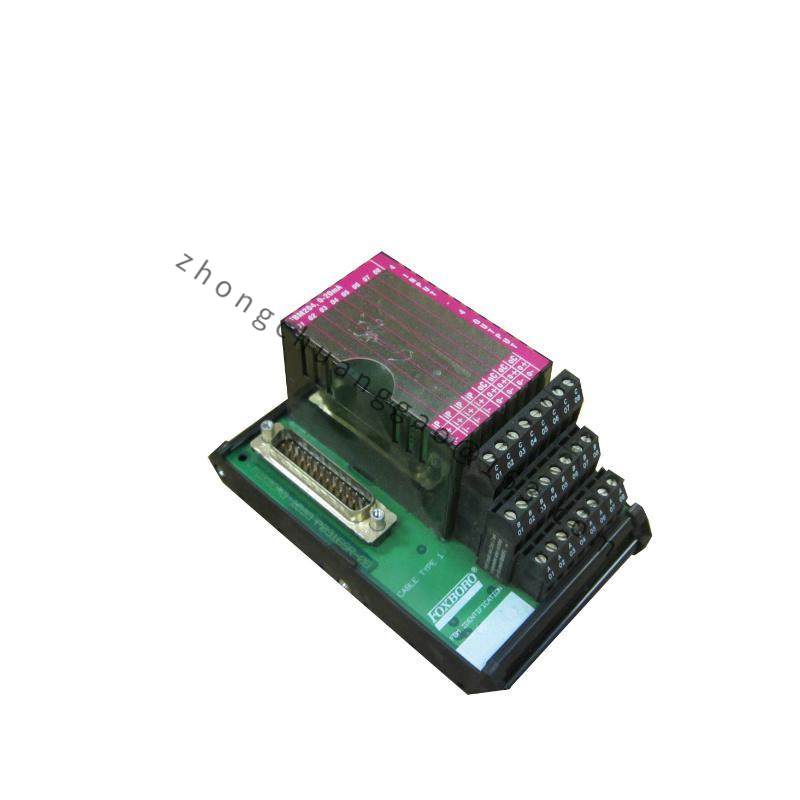

- Hardware Integration:

- Controllers: ABB AC 800M, GE RX3i.

- Fieldbus Modules: 100/200-series FBMs with RH926KW dual-cable baseplates.

- Software Tools:

- EcoStruxure Foxboro DCS v9.0+ for configuration.

- Control Core Services for network management.