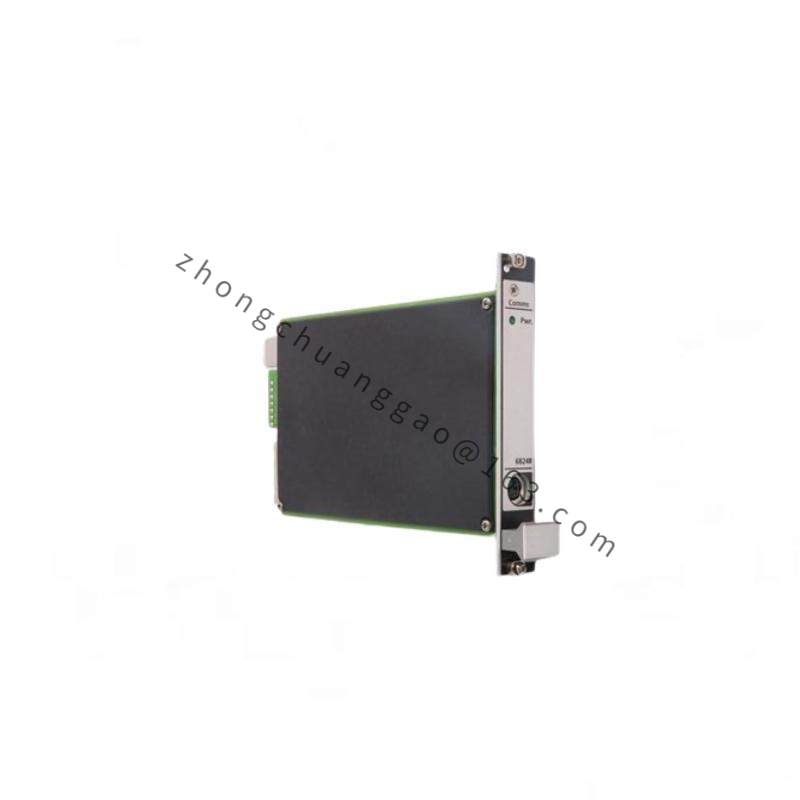

EMERSON A6824: Precision Machinery Health Monitoring Module

The EMERSON A6824 Machinery Health Monitor is a state-of-the-art diagnostic tool designed to provide real-time monitoring of industrial machinery health, ensuring optimal performance and predictive maintenance through advanced analytics.

Detailed content

Monitoring Frequency:Continuous

Data Acquisition Rate:High-Speed Sampling

Alert Thresholds:Customizable

Maintenance Recommendations:Automated

Operating Temperature Range:-40°C to 70°C

Power Consumption:Low

Communication Protocol:Ethernet, Modbus TCP/IP

Dimensions (WxDxH):150mm x 100mm x 25mm

Weight:0.5kg

IP Rating:IP67

Environmental Compliance:RoHS Compliant

Introducing the EMERSON A6824 Machinery Health Monitor, the ultimate tool for proactive machinery management. This cutting-edge solution leverages advanced analytics to monitor critical parameters in real-time, providing actionable insights for immediate corrective actions.

With its robust 220V power supply and compatibility across a wide range of operating frequencies, the A6824 ensures compatibility with diverse industrial settings. Its high measurement accuracy ensures reliable and precise data, making it a cornerstone of maintenance planning.

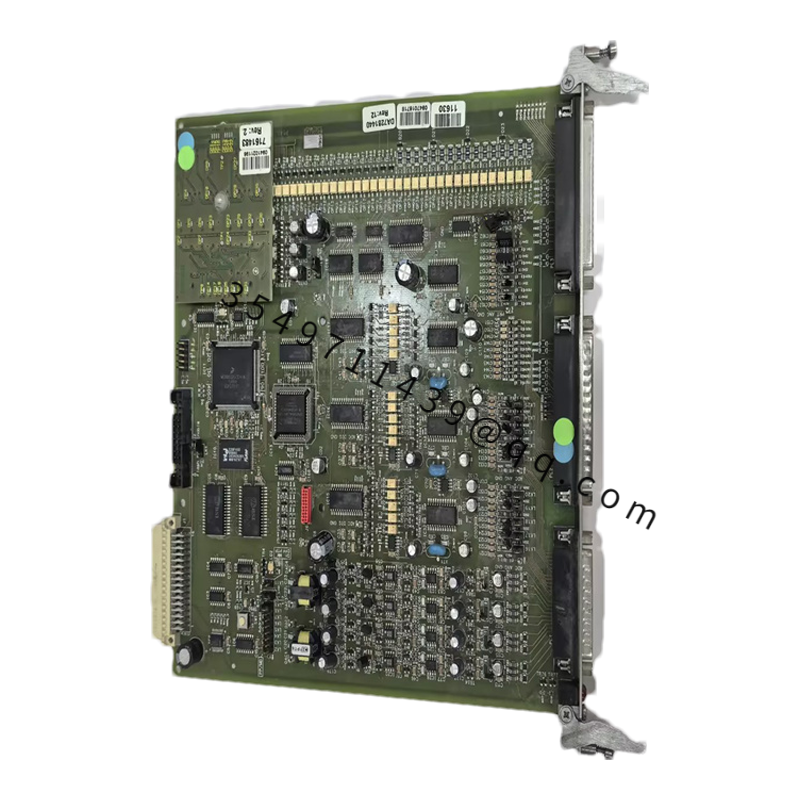

The device boasts an extensive data logging capacity, capable of storing over a decade’s worth of operational data, which can be invaluable for historical analysis and predictive maintenance scheduling. Its versatile sensor compatibility allows for a comprehensive health check-up of your machinery, covering temperature, vibration, and noise levels.

Featuring seamless communication interfaces like RS-485 and Ethernet, the A6824 facilitates easy integration with existing systems, enhancing the overall efficiency of your maintenance workflow. The built-in alarm function provides timely notifications, enabling swift response to potential issues before they escalate into costly downtime.

Engineered with durability and reliability in mind, the A6824 is a testament to EMERSON‘s commitment to quality and innovation. It stands as a pivotal component in achieving optimal machinery health, thereby maximizing productivity and minimizing maintenance costs.