Detailed content

Number of Axes:4

Control Method:Proportional, Integral, Derivative (PID) control

Maximal Output Current:10A per channel

Input Voltage Range:12-48V DC

Operating Temperature Range:-20°C to +70°C

Communication Protocol:RS-485 Modbus

Power Supply:24V DC

Module Size:86mm x 110mm x 56mm

Weight:0.5kg

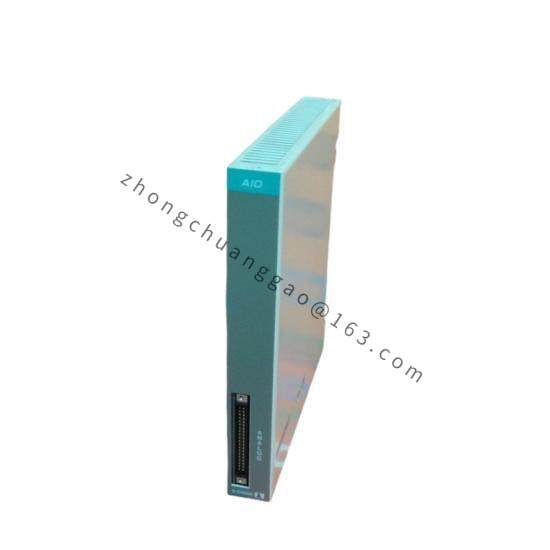

The Berkeley BXI4/2-01-B process control module is engineered with state-of-the-art technology to deliver unparalleled precision and reliability in industrial automation systems. Its compact design and robust build quality make it suitable for integration into a wide range of machinery and equipment.

Equipped with four independent control axes, this module is capable of handling complex multi-axis movements, ensuring smooth operation and enhanced productivity in applications such as CNC machining, robotics, and material handling.

Featuring a 24V DC power supply, the module operates efficiently across different industrial environments, providing stable control even under varying conditions. Its modular design allows for easy setup and maintenance, reducing downtime and enhancing operational efficiency.

With support for MODBUS RTU/TCP communication protocols, the Berkeley BXI4/2-01-B facilitates seamless integration with existing control systems, enabling remote monitoring and control from a central location. This feature is particularly beneficial for large-scale industrial installations where centralized management is crucial.

The module is designed to withstand harsh industrial environments, offering an operating temperature range from -20°C to +60°C, ensuring reliable performance in extreme conditions. Additionally, its lightweight yet durable construction ensures minimal strain on mounting structures and easy installation in confined spaces.