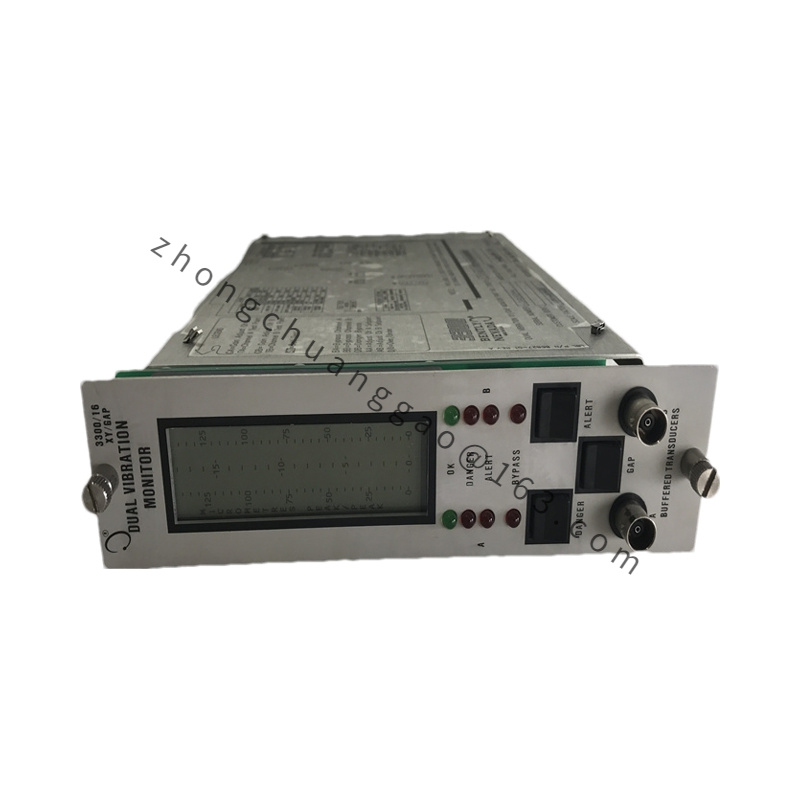

BENTLY NEVADA 3300/65 Dual Probe Monitor, Advanced Monitoring for Industrial Automation

The BENTLY NEVADA 3300/65 Dual Probe Monitor offers unparalleled accuracy and reliability in monitoring shaft vibrations and displacements in critical industrial machinery, ensuring optimal performance and safety.

Detailed content

Input Impedance:10 kΩ

Power Consumption:Nominal consumption of 1.5 watts

Supply Voltage:-24 Vdc

Signal Combination:Shaft relative displacement and casing vibration

Installation Type:Single-axis dual-probe installation

The Bently Nevada 3300/65 Dual Probe Monitor integrates the functionality of both a proximity transducer and a velocity transducer, providing an accurate assessment of the shaft’s absolute vibration. This combination ensures reliable and precise monitoring of critical machinery conditions.

Equipped with advanced signal processing capabilities, the monitor offers real-time feedback, enabling operators to quickly identify potential issues before they escalate into major failures, thus enhancing operational efficiency and reducing downtime.

Designed with durability and reliability in mind, the Bently Nevada 3300/65 Dual Probe Monitor is suitable for harsh industrial environments. Its robust construction withstands extreme temperatures and mechanical stresses, ensuring consistent performance over long periods.

User-friendly interface and intuitive operation facilitate easy setup and maintenance. The monitor provides clear visual and audible alerts, enabling immediate action when necessary, ensuring continuous protection against machinery malfunctions.

Backed by extensive industry experience, the Bently Nevada 3300/65 Dual Probe Monitor is a trusted solution for industries ranging from power generation to manufacturing. It supports a wide range of applications, from rotating machinery in power plants to heavy machinery in automotive manufacturing lines.