Detailed content

Technical Specifications:

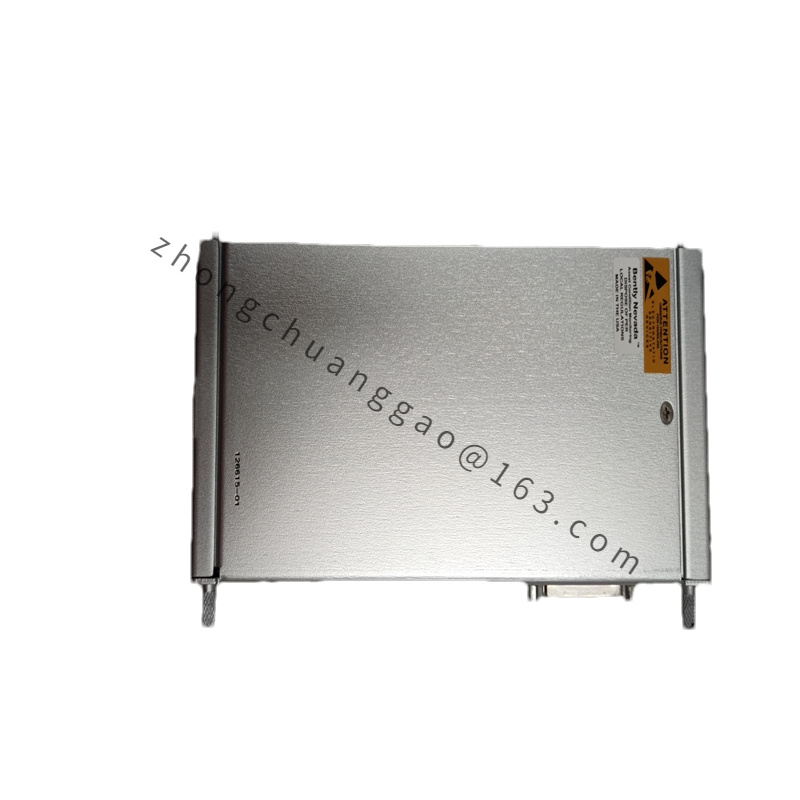

- Model: Bently 9200-06-02-10-00

- Type: Vibration Monitor/Condition Monitoring System

- Power Supply: Typically operates on 24V DC.

- Input Channels: Designed to accept inputs from multiple vibration sensors, such as proximity probes.

- Measurement Range: Capable of measuring various vibration parameters including displacement, velocity, and acceleration.

- Output: Offers analog outputs (4-20 mA) and digital outputs, supporting integration with control systems.

- Signal Processing: Features advanced digital signal processing for accurate and reliable vibration analysis.

- Communication: May include digital communication protocols like HART for data integration with process control systems.

Features:

- Real-Time Monitoring: Provides real-time vibration data to monitor equipment condition continuously.

- Alarm Functionality: Equipped with alarm capabilities to alert operators when vibration exceeds preset thresholds.

- Data Analysis: Offers capabilities for detailed data analysis and trend monitoring to identify potential issues before they lead to failures.

- Ease of Use: User-friendly interface for configuration and monitoring, making it accessible for operators and maintenance personnel.

Applications:

- Industrial Equipment: Used in various industries, including power generation, oil and gas, and manufacturing.

- Rotating Machinery: Suitable for monitoring critical rotating machinery such as pumps, compressors, turbines, and motors.

- Predictive Maintenance: Ideal for implementing predictive maintenance strategies by providing early warnings of equipment issues.

Benefits:

- Improved Equipment Reliability: Helps in detecting potential problems early to prevent unexpected failures.

- Reduced Maintenance Costs: By enabling predictive maintenance, it reduces the need for emergency repairs and associated costs.

- Enhanced Safety: Early detection of abnormal vibration conditions helps in preventing hazardous situations.