Detailed content

1. Technical Specifications

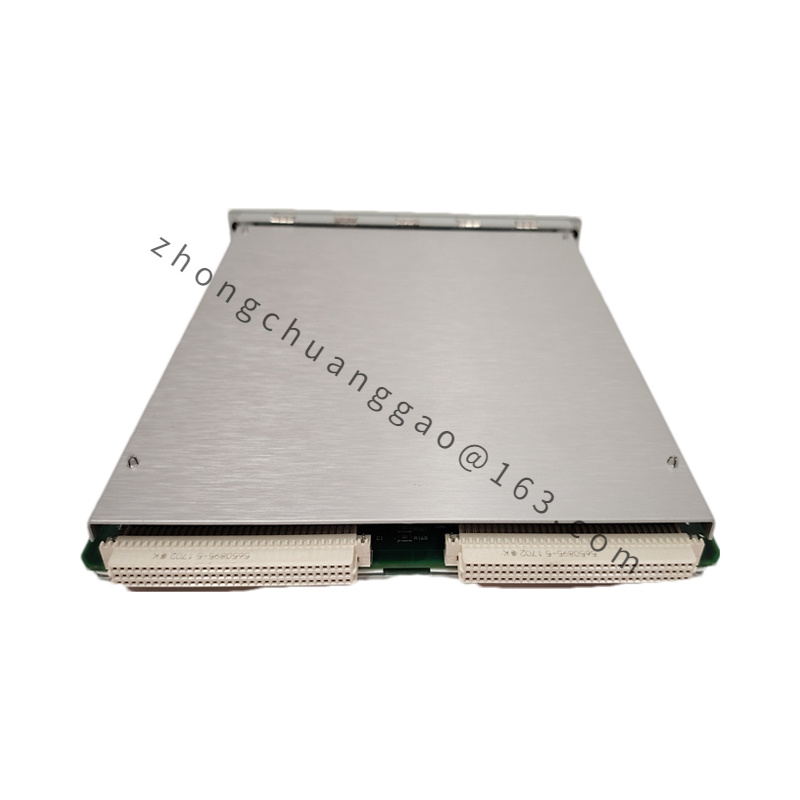

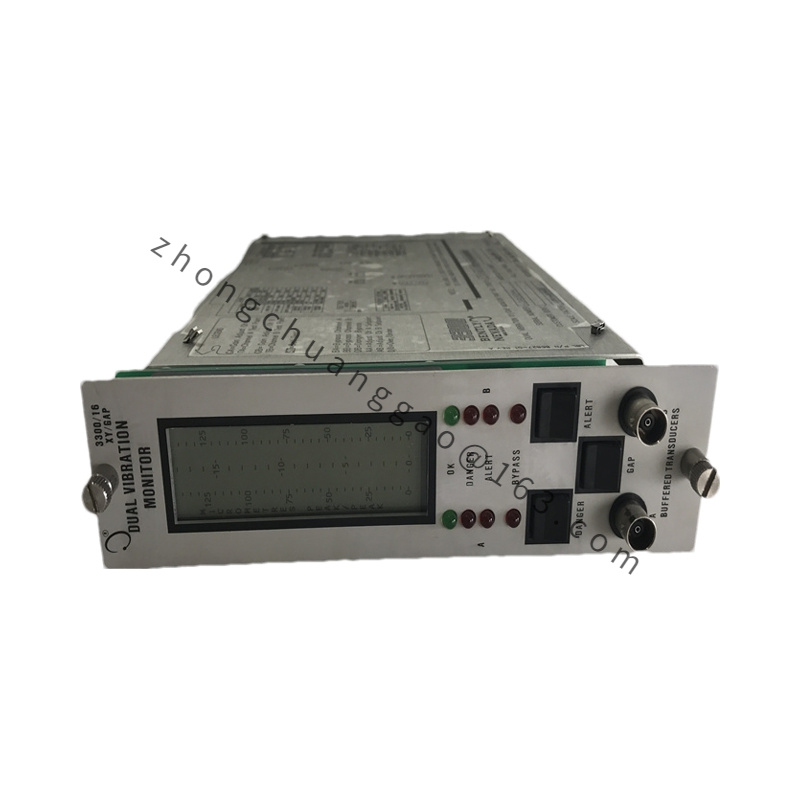

- Model: 3500/65 145988-02

- Type: Rotor Dynamics Monitoring Module

- Dimensions: Specific dimensions are detailed in the technical manual.

- Weight: Typically around 1.5 lbs (0.68 kg).

- Power Supply: Operates with a nominal voltage of 24V DC.

- Temperature Range: Designed to operate in temperatures ranging from -40°C to +70°C (-40°F to +158°F).

- Communication: Interfaces with the Bently Nevada 3500 Series System, which communicates over a proprietary high-speed serial bus.

2. Functionality and Features

- Rotor Dynamics Monitoring: Measures and monitors key dynamic characteristics of rotating machinery, including shaft vibrations, shaft displacement, and other critical parameters.

- Data Acquisition: Capable of acquiring and processing vibration data, rotational speed, and other dynamics essential for accurate machinery health monitoring.

- Alarm and Shutdown: Configurable for real-time alarms and automatic shutdown responses based on pre-set thresholds, helping to protect machinery from damage.

- Integration: Integrates seamlessly with the Bently Nevada 3500 Series rack and supports the overall machinery protection system.

- Signal Processing: Advanced signal processing capabilities for accurate data interpretation and diagnosis.

- Modular Design: Designed for ease of maintenance and replacement, with modular components that simplify system upgrades and troubleshooting.

- Diagnostics: Includes diagnostic capabilities to help identify issues within the module or the machinery it monitors.

3. Applications

- Industrial Machinery: Used extensively in various industrial applications to monitor and protect critical rotating machinery such as gas turbines, steam turbines, compressors, and pumps.

- Power Generation: Commonly employed in power generation facilities to ensure the reliability and safety of turbines and other critical rotating equipment.

- Oil & Gas: Applied in the oil and gas industry for monitoring equipment such as centrifugal compressors and pump systems.

- Chemical and Petrochemical Plants: Used to monitor and protect machinery in chemical processing and petrochemical industries, where equipment reliability is crucial.

- Marine and Aerospace: Implemented in marine and aerospace applications to ensure the safe operation of critical machinery.

4. Installation and Maintenance

- Installation: Typically installed in a Bently Nevada 3500 Series Rack. The module is mounted in a standard 19-inch rack and connected via the Bently Nevada system’s communication bus.

- Maintenance: Regular checks are required to ensure proper operation. Periodic calibration and verification against known standards are recommended to maintain accuracy and reliability.

- Support: Maintenance and support often involve checking module connections, recalibrating sensors, and ensuring firmware is up to date.

5. Related Products and Systems

- Bently Nevada 3500 Series: The 3500/65 module is part of the broader 3500 Series, which includes various other modules for vibration monitoring, control, and protection.

- Bently Nevada System: Integrates with other Bently Nevada equipment and software for comprehensive machinery health management and monitoring solutions.

6. Technical Support and Documentation

- Documentation: Detailed specifications, installation instructions, and maintenance guidelines can be found in the official Bently Nevada 3500/65 documentation and user manuals.

- Technical Support: For specific support, troubleshooting, or additional technical information, contacting Bently Nevada (part of Baker Hughes) directly or visiting their official website is recommended.

.jpg)