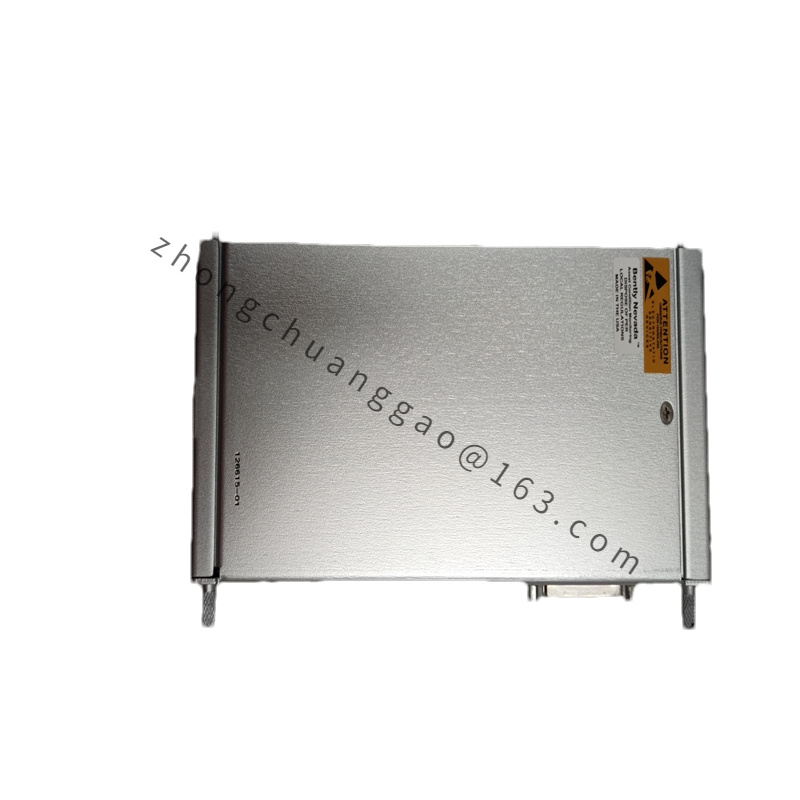

Bently 3500/53 133388-01

The Bently 3500/53 133388-01 is a module in the Bently Nevada 3500 Series, designed for high-precision machinery monitoring and protection. This module is specifically a 4-Channel Keyphasor® Module, which is used for monitoring rotational speed and phase angles in rotating machinery.

Detailed content

Technical Specifications

- Model: Bently 3500/53 133388-01

- Type: 4-Channel Keyphasor® Module

- Channels: Supports four channels, allowing for the simultaneous monitoring of up to four Keyphasor sensors.

- Measurement Capabilities:

- Speed Measurement: Accurately measures the rotational speed of machinery.

- Phase Measurement: Provides precise phase angle measurements, which are crucial for detecting alignment issues and phase discrepancies.

- Output Signal:

- Analog Outputs: Provides 4-20 mA analog outputs for each channel, delivering continuous measurement data for speed and phase.

- Relay Outputs: Equipped with relay outputs for alarm conditions, activating when speed or phase measurements exceed predefined thresholds.

- Frequency Response: Capable of measuring a wide range of frequencies, suitable for various rotating machinery applications. Detailed frequency response characteristics are available in the datasheet.

- Operating Temperature Range: Typically operates within a temperature range of -40°C to +70°C (-40°F to +158°F), ensuring reliable operation in diverse industrial environments.

- Protection Rating: Generally features an IP20 rating, providing protection against dust and accidental contact. Exact protection details should be confirmed in the datasheet.

Features

- Multi-Channel Monitoring: Allows simultaneous monitoring of up to four Keyphasor sensors, providing comprehensive speed and phase measurement data.

- High Precision: Delivers accurate measurements of rotational speed and phase angles, essential for proper machinery alignment and condition monitoring.

- Real-Time Data Processing: Processes data in real-time, enabling immediate insights and prompt responses to changes in machinery conditions.

- Alarm and Diagnostic Functions: Includes alarm and diagnostic features to alert operators of potential issues and assist in troubleshooting.

- Integration with 3500 Series: Integrates seamlessly with other modules in the Bently 3500 Series, supporting a unified machinery monitoring and protection system.

Application Scenarios

- Speed and Phase Measurement: Ideal for precise measurement of rotational speed and phase angles in machinery such as turbines, compressors, and generators. Essential for ensuring proper operation and detecting potential issues.

- Machinery Protection: Provides critical data for machinery protection systems by monitoring speed and phase, helping to prevent failures and ensure reliable performance.

- Condition Monitoring: Used in condition monitoring systems to deliver accurate data on machinery speed and phase, contributing to optimal performance and early detection of issues.

- Predictive Maintenance: Supports predictive maintenance strategies by providing detailed measurements that can forecast potential problems and aid in proactive maintenance planning.

Usage Considerations

- Installation: Proper installation is crucial for accurate measurement. Ensure that the module is correctly mounted and connected to the Keyphasor sensors.

- Calibration: Regular calibration may be required to maintain measurement accuracy and reliable operation.

- System Integration: Verify compatibility with other Bently 3500 Series modules and monitoring systems to ensure a comprehensive and integrated solution.