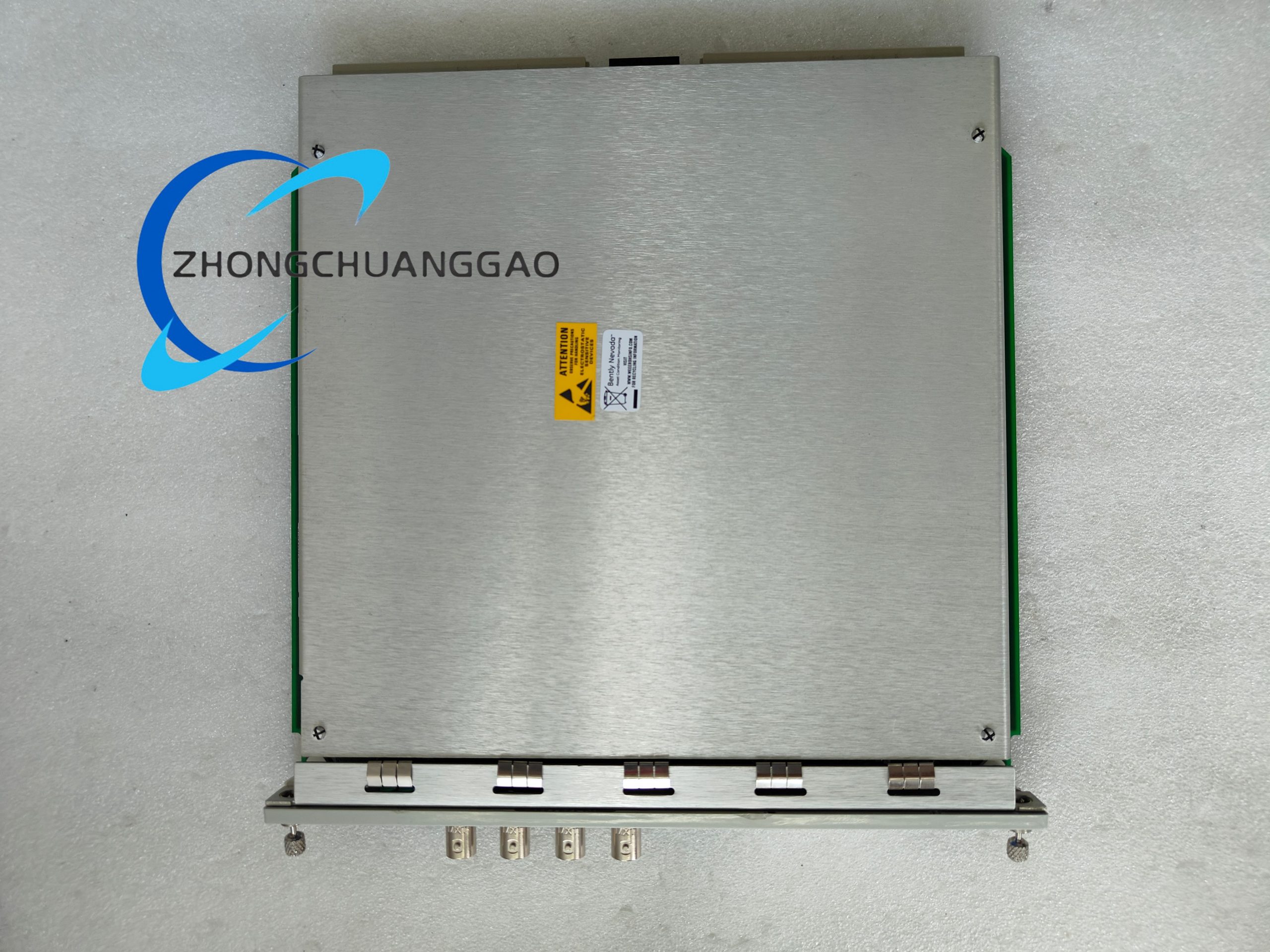

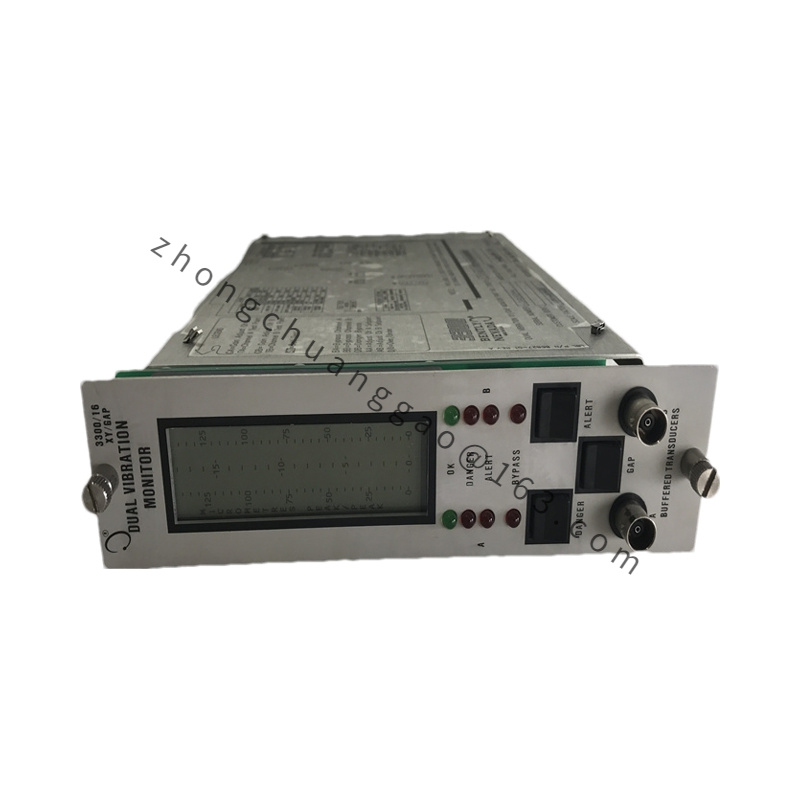

Bently 3500/44M 176449-03

Product Introduction:

A high-performance 4-channel monitor engineered for aeroderivative gas turbines. It processes signals from accelerometers, velocity sensors, eddy-current probes and dynamic pressure transducers to deliver combustion instability, blade-pass tracking, 1X vibration vectors and multi-mode alarms with ±0.1 % accuracy. The module is SIL-capable and certified for hazardous areas worldwide.

A high-performance 4-channel monitor engineered for aeroderivative gas turbines. It processes signals from accelerometers, velocity sensors, eddy-current probes and dynamic pressure transducers to deliver combustion instability, blade-pass tracking, 1X vibration vectors and multi-mode alarms with ±0.1 % accuracy. The module is SIL-capable and certified for hazardous areas worldwide.

Technical Specifications:

-

Channels: 4 high-speed dynamic inputs

-

Input Types: 3300 XL proximity, Velomitor, IEPE accelerometer, piezo pressure

-

ADC Resolution: 24-bit

-

Sampling Rate: 51.2 kHz per channel

-

Frequency Range: 0.05 Hz – 20 kHz user-configurable

Detailed content

-

FFT Points: Up to 65,536

-

On-board Storage: 64 GB SSD for waveform & spectral archives

-

Measurements: Radial vibration, axial displacement, 1X vector tracking, combustion instability index

-

Alarm Set-points: 8 groups, user-programmable low/high speed levels

-

Communication: Back-plane + 10/100BASE-T Ethernet for direct data export

-

Power: 24 VDC from rack, 7.8 W max

-

Operating Temperature: –40 °C to +85 °C

-

Storage Temperature: –40 °C to +85 °C

-

Humidity: 95 % RH non-condensing

-

Protection: IP20 front, epoxy-sealed electronics

-

Dimensions: 241.3 × 24.4 × 241.8 mm

-

Weight: 0.91 kg

-

Agency Approvals: ATEX Ex ia IIC T4 Ga, IECEx, CSA Class I Div 2, SIL 2 capable

Functional Features:

-

24-bit ADC captures micro-variations in vibration signals

-

51.2 kHz sampling detects high-frequency blade-pass harmonics

-

64 GB SSD archives pre- and post-event waveforms for root-cause analysis

-

Ethernet port exports real-time spectra to 170180-01-00 software or plant historian

-

Combustion instability index distinguishes flame-out from mechanical vibration

-

Hot-swappable without rack shutdown

Application Scenarios:

-

Combined-cycle gas turbine high-pressure rotor – detects 3× speed harmonics indicative of blade cracking months before failure

-

LNG centrifugal compressor – identifies impeller unbalance via side-band analysis around blade-pass frequency

-

Offshore drilling rig mud-pump gearbox – captures bearing defect frequencies in 20 kHz band and transmits data to onshore engineers

.jpg)