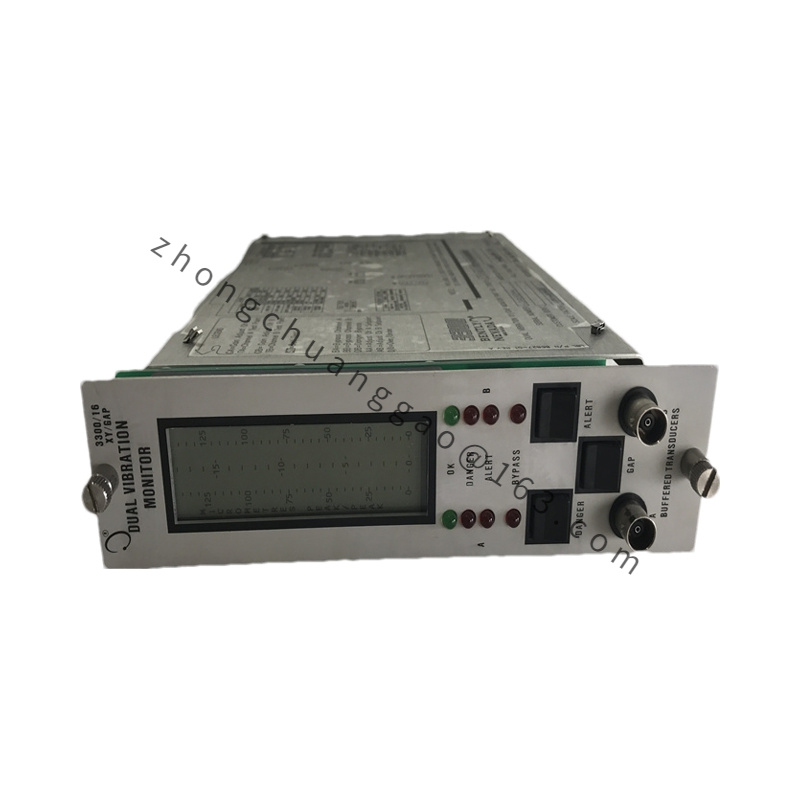

Bently 3500/25 125792-01

The Bently 3500/25 125792-01 is part of Bently Nevada’s 3500 Series, which is renowned for its advanced machinery protection and condition monitoring systems. The 3500/25 model specifically focuses on monitoring and analyzing the performance of machinery to ensure its reliability and safety in industrial environments.

Detailed content

Technical Specifications

- Type: Machinery Protection System.

- Model: 3500/25.

- Part Number: 125792-01.

- Inputs:

- Vibration: Accepts inputs from vibration sensors such as accelerometers.

- Speed: Interfaces with speed sensors for accurate rotational speed measurement.

- Measurement Range: Designed to measure a wide range of vibration frequencies, amplitudes, and rotational speeds.

- Output Type: Provides both analog and digital outputs compatible with industrial control and monitoring systems.

- Power Supply: Operates on standard industrial power supplies; detailed specifications can be found in the product datasheet.

- Temperature Range: Built to operate within industrial temperature ranges; details available in the datasheet.

- Communication: Includes communication interfaces for integration with existing plant control systems.

Features

- Precision Measurement: High-precision sensors for accurate vibration and speed measurement.

- Advanced Diagnostics: Features advanced diagnostic capabilities to identify and address potential issues.

- Robust Design: Engineered to withstand harsh industrial conditions, including extreme temperatures and mechanical stresses.

- Flexible Integration: Easily integrates with existing control and monitoring systems.

- User-Friendly Interface: Offers intuitive interfaces for easy setup and operation.

Applications

- Machinery Protection: Continuous monitoring of critical machinery to prevent failures and ensure operational efficiency.

- Condition-Based Maintenance: Supports maintenance strategies based on real-time condition data of the machinery.

- Predictive Maintenance: Helps in predicting potential machinery issues before they occur, facilitating proactive maintenance.

- Process Optimization: Enhances machinery performance and reliability through detailed vibration and speed analysis.