Detailed content

Technical Specifications

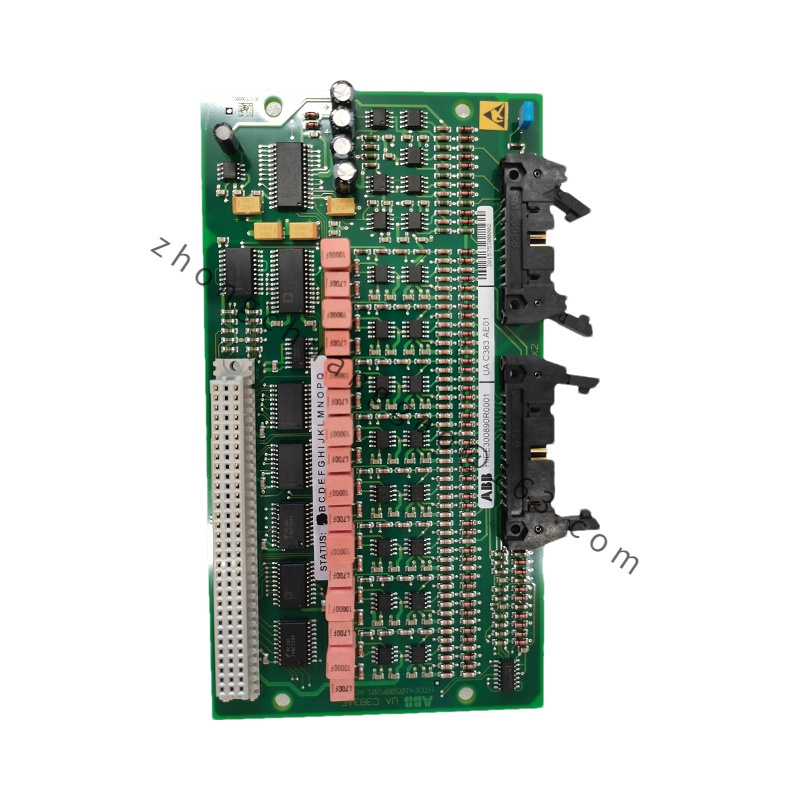

Interface: UAC383AE01 offers a variety of communication interfaces, including RS-232/422/485, Ethernet, and USB ports, facilitating seamless integration with other devices and systems.

Display: Equipped with a high-resolution display capable of operating within a wide temperature range, ensuring clear visibility in various industrial environments.

Computing Power: Introduces enhanced computing capabilities and memory, allowing for automation of complex machine control processes.

Operating Temperature: Designed for operation within a wide temperature range, often specified as 0°C to 50°C, ensuring reliability in harsh industrial settings.

Functional Characteristics

Distributed Control: Adopts a distributed control architecture, distributing control functions across multiple nodes, thereby improving system stability and reliability.

Modular Design: Facilitates easy system expansion and maintenance, allowing for flexible addition or replacement of functional modules as needed.

High-Performance Processor: Equipped with a high-performance processor and communication interfaces, enabling real-time monitoring and rapid response to production processes.

Compatibility: Supports multiple industrial communication protocols such as Modbus, Profibus, and Ethernet, allowing for integration with devices from different manufacturers.

Robust Hardware and Software: Utilizes reliable hardware and software design to ensure stable system operation and minimize the risk of system failures.

Application Scenarios

ABB UAC383AE01, as part of a DCS, is widely used in various industrial applications, including:

Chemical Industry: For process monitoring and control in chemical reactions, mixing, separation, and other processes.

Oil and Gas: Monitoring and controlling oil wells, pipelines, compressor stations, and other equipment in oil and gas production systems.

Power Generation and Distribution: Controlling generators, transformers, switchgear, and other equipment in power plants and distribution systems.

Manufacturing: Automating production lines in industries such as automotive, metalworking, and electronics manufacturing.

Water and Wastewater Treatment: Monitoring and controlling pumps, filters, and treatment equipment in water and wastewater treatment plants.

Food and Beverage Processing: Automating filling lines, sterilization equipment, mixers, and other machinery in food and beverage factories.

.jpg)