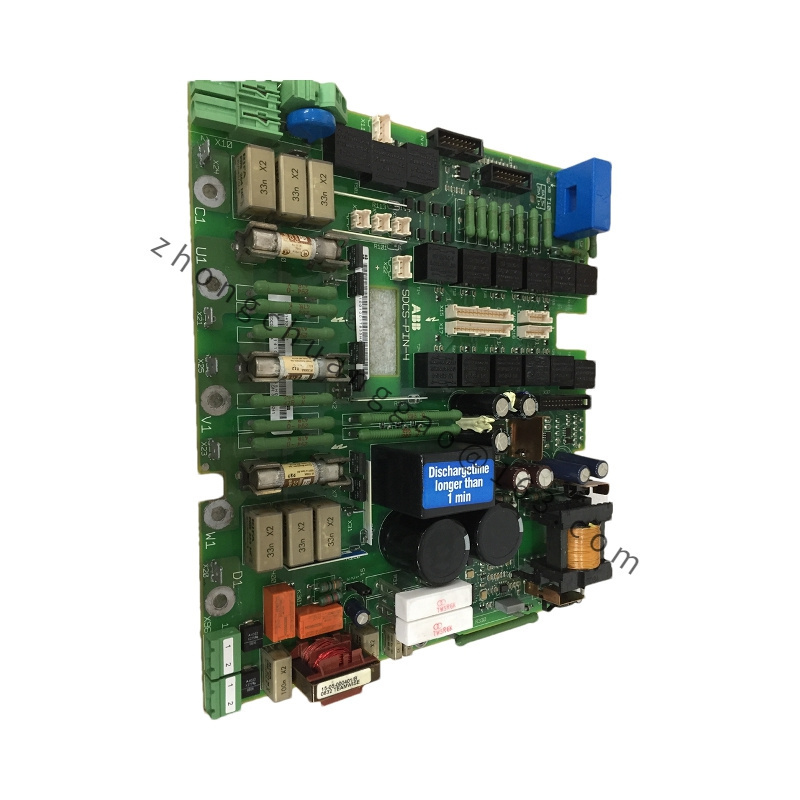

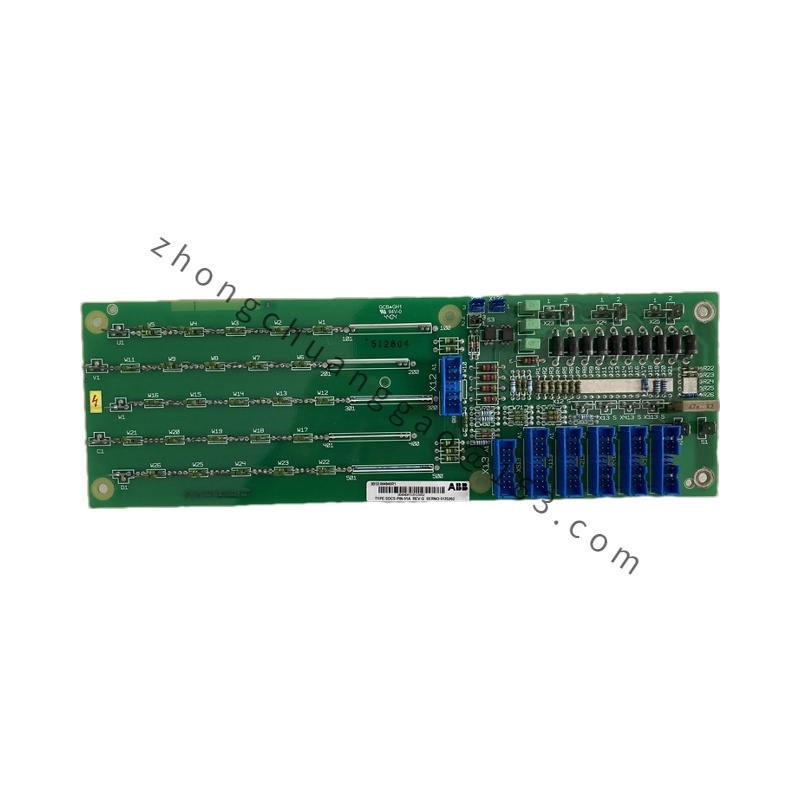

ABB SDCS-PIN-4-COAT

Data Electrical Interface:

9-pin Sub_D socket connector, pin definitions compliant with Profibus DP protocol specifications.

Supports Profibus DP bus standard.

Communication rates: 9.6kBit/s, 19.2kBit/s, 45.45kBit/s, 93.75kBit/s, 187.5kBit/s, 500kBit/s, 1.5MBit/s, 6MBit/s, and 12MBit/s.

Rate settings: Automatic recognition or dial switch setting.

Detailed content

Signal delay (electrical port): ≤11Bit.

Optical Fiber Characteristics:

Optical wavelengths: Multimode 850nm, 1310nm; Single-mode 1310nm, 1550nm.

Transmission fibers: Multimode 50/125μm, 62.5/125μm, 100/140μm; Single-mode 8.3/125μm, 9/125μm, 10/125μm.

Transmission distances: Multimode up to 2Km, Single-mode up to 20Km, with options for longer distances.

Fiber interface types: SC, FC, ST optional, with SC being the standard configuration.

Signal delay (optical port): ≤1.6us/node.

Protection Features:

4000V lightning protection, 1.5A overcurrent protection, and 600W surge protection.

Functional Features

Flexibility: Can be configured into various fiber optic networks, offering logical independent dual-bus electrical interfaces for backup or single-device access to dual-redundant bus systems.

Redundancy: Implements dual-fiber ring network redundancy. In case of a fiber failure, the system reconstructs the network link within 10ms, ensuring uninterrupted communication and self-healing protection.

Easy Integration: Uses ABB’s proprietary Ci-ring protocol, eliminating the need for configuration, root nodes, and simplifying installation and debugging processes.

High-Speed Communication: Supports multiple communication rates up to 12MBit/s, enabling efficient data transmission.

Application Scenarios

ABB SDCS-PIN-4-COAT is designed for use in industrial automation systems where reliable and high-speed communication is crucial. Its versatility and redundancy features make it suitable for various applications, including but not limited to:

Process Control Systems: Used in Profibus DP networks for process monitoring and control in chemical plants, oil and gas facilities, and other industrial environments.

Manufacturing Automation: Enables seamless communication between PLCs, robots, and other automation devices in production lines, enhancing overall productivity and efficiency.

Power Generation and Distribution: Supports communication in power plants and substations, ensuring reliable operation of control systems for generators, transformers, and other equipment.

Transportation Systems: Utilized in railway signaling, traffic control, and other transportation-related automation systems, where real-time communication is essential for safety and efficiency.

.jpg)