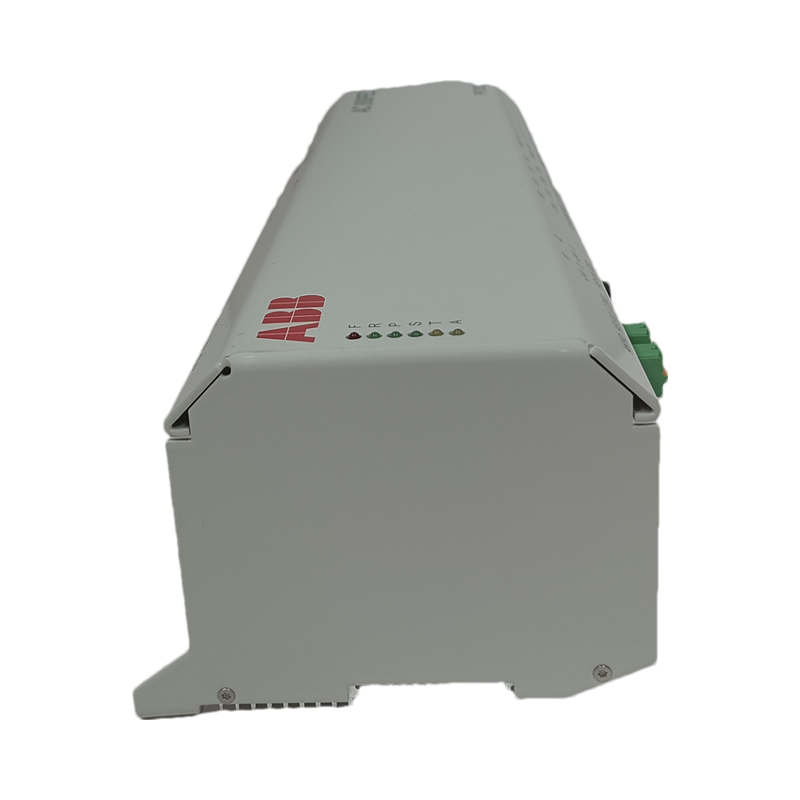

ABB PPD513A10-111111

Technical Specifications (Inferred from Related Models)

- Input Voltage: Likely supports 90–264V AC or 120–375V DC to accommodate global power standards, consistent with ABB’s PPD513 series 1.

- Output Voltage: Programmable 0–24V DC with adjustable current up to 10A, enabling precise load management in distributed I/O systems 12.

- Efficiency: Achieves ≥90% energy conversion efficiency, minimizing heat dissipation and optimizing energy usage .

Detailed content

- Environmental Ratings:

- Operational temperature range: -25°C to +70°C (suitable for harsh industrial environments).

- Humidity resistance: 95% RH (non-condensing) .

- Dimensions: Compact 130 x 40 x 120 mm design for DIN-rail mounting, ensuring space-efficient installation .

- Redundancy Support: Likely supports parallel configuration with redundant power modules to ensure continuous operation in critical applications .

Functional Features

- Programmable Power Management:

- Configurable voltage and current via RS-232/RS-485 or industrial bus protocols (e.g., Profibus, Modbus), allowing dynamic adjustments for varying loads .

- Comprehensive Protection:

- Equipped with overvoltage (OVP), overcurrent (OCP), and overtemperature (OTP) safeguards to prevent equipment damage during fault conditions .

- Real-Time Monitoring:

- Integrates sensors for real-time tracking of voltage, current, and power factor, enabling predictive maintenance and energy optimization .

- Modular Architecture:

- Works seamlessly with S800 I/O modules and AC800PEC controllers, supporting scalable configurations with additional analog/digital channels .

- IGCT Integration:

- Incorporates Integrated Gate-Commutated Thyristor (IGCT) technology for high-power applications, ensuring low conduction losses and high switching reliability .

Application Scenarios

- Industrial Automation:

- Powers motor drives, conveyor systems, and PLCs in manufacturing plants, ensuring stable operation and energy efficiency .

- Manages power distribution in substation environments, protecting critical equipment from overloads .

- Process Control:

- Regulates pump speeds and chemical dosing in water treatment facilities using PID algorithms .

- Monitors HVAC systems in smart buildings, balancing energy consumption and environmental comfort .

- Power Electronics:

- Optimizes synchronous generator excitation in power plants, stabilizing grid connections and reducing harmonic distortion .

- Supports renewable energy systems (e.g., solar inverters) by managing power conversion and grid synchronization .

- LED Lighting Systems:

- Controls brightness, color temperature, and dimming profiles in commercial and industrial settings, integrating with smart building automation .

Compliance and Certifications

- Standards: Meets IEC 61000-6-2 (EMC immunity) and IEC 60947-2 (low-voltage switchgear) requirements for industrial use .

- Safety: Compliant with UL 508 (industrial control equipment) and CE marking for European Union directives .

- Environmental: Adheres to RoHS and REACH standards for material compliance 10.

Integration and Compatibility

- System Integration: Seamlessly interfaces with ABB Ability™ System 800xA, enabling centralized monitoring and data analytics across plant-wide operations .

- Hardware Compatibility: Works with AC800PEC I/O modules and ACS880 drives for unified control and diagnostics .

- Software Tools: Configurable via ABB Compact Control Builder, supporting IEC 61131-3 programming languages (ladder logic, function block diagram) and MATLAB/Simulink for model-based development .

Design Philosophy

The PPD513A10-111111 aligns with ABB’s focus on reliability and efficiency, combining compact design with advanced power management. Its modular architecture and redundancy support reduce installation complexity, while high-speed processing ensures optimal performance in fast-paced industrial environments. By integrating with ABB’s broader automation ecosystem, it delivers scalable solutions for mission-critical applications across industries.

Discover our other products

GIDDINGS & LEWIS REP/EXCH BIO 4CH ANALOG INPUT / M.1017.6270

GIDDINGS & LEWIS REP/EXCH DRIVE, DSA 022-460-S / R.1301.8656

GIDDINGS & LEWIS PIC 900 CPU / 572-03510-51 R2 / 502-03510-51

Giddings & Lewis FSM610, 401-34324-01 Servo Motor

DANAHER MOTION 502-03680-11R1 / 5020368011R1

Giddings & Lewis M.1016.9677 R1 PiC900 Programmable Industrial Computer

DANAHER MOTION 502-03641-02R0 / 5020364102R0

DANAHER MOTION M.1016.8892 / M10168892

GIDDINGS & LEWIS PiC 900 502-03552-20R3

Giddings and Lewis 401-56367-01 TrueView 3360TH Panel PC

GIDDINGS & LEWIS REP/EXCH BIO 4CH ANALOG INPUT / M.1017.6270

GIDDINGS & LEWIS REP/EXCH DRIVE, DSA 022-460-S / R.1301.8656

GIDDINGS & LEWIS PIC 900 CPU / 572-03510-51 R2 / 502-03510-51

Giddings & Lewis FSM610, 401-34324-01 Servo Motor

DANAHER MOTION 502-03680-11R1 / 5020368011R1

Giddings & Lewis M.1016.9677 R1 PiC900 Programmable Industrial Computer

DANAHER MOTION 502-03641-02R0 / 5020364102R0

DANAHER MOTION M.1016.8892 / M10168892

GIDDINGS & LEWIS PiC 900 502-03552-20R3

Giddings and Lewis 401-56367-01 TrueView 3360TH Panel PC

.jpg)