Detailed content

Technical Specifications

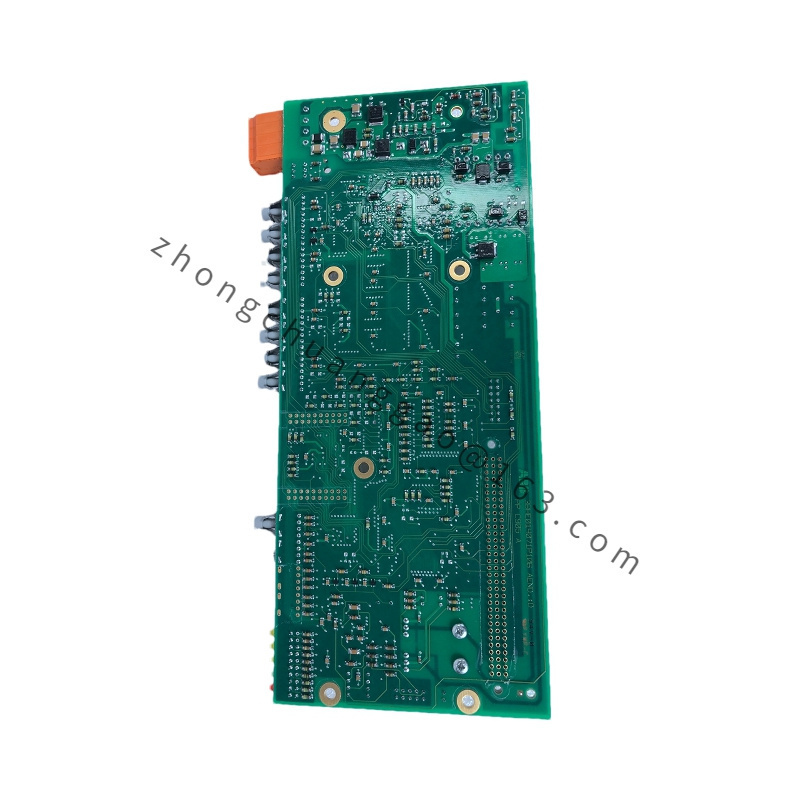

Brand: ABB

Model: PPC905AE101

Input/Output:

Digital Input Points: 10

Rated Voltage: 24V DC, 4mA

Maximum Continuous Allowable Voltage: 30V DC

Surge Voltage: 35V DC, 0.5s

Logic “0” Voltage Range: 5V DC, 1mA

Logic “1” Voltage Range: 15V DC, 1mA

Input Delay: 4.5ms

Signal Input Type: PNP/NPN, Photoelectric Isolation (Field to Logic) 500V AC, 1 minute

Maximum Allowable Leakage Current: 1mA

Cable Length (Shielded): 500m

Cable Length (Unshielded): 300m

Digital Output Points: 6

Output Type: Relay

Output Voltage: 24V DC or 250V AC

Rated Voltage: 5-30V DC / 20-250V AC

Rated Current: 2.0A

Common Terminal Rated Current: 10A

PPC905AE101 Current (Max.): 5A, 4s @ 10% Duty Cycle

Lamp Load: 30W DC / 200W AC

Contact Mechanical Life: 10,000,000

Turn-on Resistance: 0.2Ω

Output Delay: 10ms

Cable Length (Shielded): 500m

Cable Length (Unshielded): 150m

Electrical Parameters:

Bus Consumption Current: 80mA

Total Power Consumption: 3W

Functional Characteristics

Programmability: Allows users to create custom control logic and algorithms to meet specific application requirements.

Multi-Channel Support: With 10 digital input points and 6 digital output points, it can simultaneously monitor and control multiple devices or processes.

Real-Time Control: Capable of performing control tasks in real-time or near real-time conditions to ensure fast and accurate system response.

Communication Interfaces: Typically supports multiple communication interfaces for data exchange and communication with other control devices, sensors, and computers.

Strong Anti-Interference Performance: Ensures stable operation in industrial environments with potential electromagnetic interference.

Industrial Grade Standard: Designed to meet the requirements of industrial environments, with high durability and stability.

Application Scenarios

Industrial Automation: Used in automation systems to control production lines, machine devices, valves, actuators, etc., for automated production and process control.

Process Control: Monitors and controls various process parameters in industries such as chemicals, petrochemicals, and oil and gas, ensuring process stability and safety.

Power System Control: In power systems, it can be used to monitor and control generators, transformers, switchgear, and power distribution systems.

Transportation and Logistics: Controls equipment such as conveyor belts, elevators, lifts, and robots for material handling, sorting, and distribution.

Building Automation: Controls lighting, HVAC systems, security systems, and access control systems in buildings to improve energy efficiency and comfort.

Data Acquisition and Monitoring: Used in data acquisition systems to monitor sensor and instrument data, such as temperature, humidity, and pressure, for real-time monitoring and data recording.

.jpg)

.jpg)