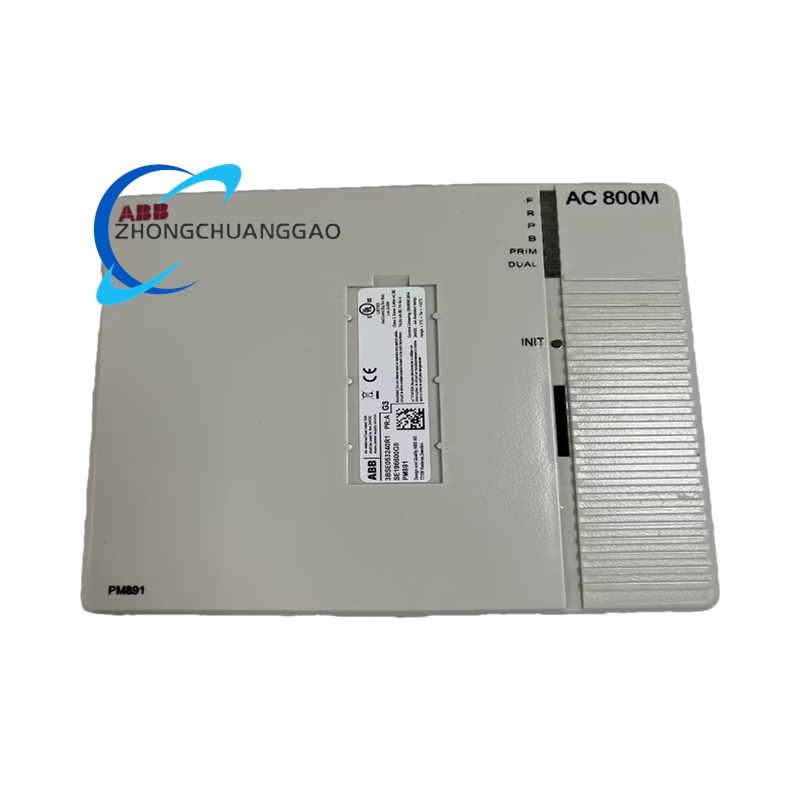

ABB PM891K01 3BSE053241R1–Central Processing Unit for System 800xA

- Technical Specifications

- Processor Architecture: It adopts PowerPC 604e architecture, and some models are equipped with a 450 MHz MPC8270 processor. There are also versions with ARM Cortex – A53 quad – core 1.9 GHz processors.

- Memory: It usually has 128 MB RAM and 4 MB flash memory, and some high – end models are equipped with 2 GB DDR4 RAM and 4 GB eMMC Flash (3.2 GB available to users).

- Communication Interface: It supports RS – 232, RS – 485, and Ethernet interfaces. There are 2 Ethernet ports (10/100 Mbit/s or Gigabit Ethernet), and some models are also equipped with 1 USB 3.0 port.

- Backplane Bus: Some models support ABB AF600 backplane bus with a bandwidth of 600 Mbps, which is downward – compatible with AF400.

- Power Supply: The power supply is 24 V DC, with a range of ±30%, and the typical power consumption is 7.5 W.

- Operating Temperature: The operating temperature range is generally – 25°C to +60°C, and some models can reach – 25°C to +70°C.

- Size and Weight: The size is about 102.5 mm×102.5 mm×32 mm, and the weight is about 2.1 kg.

- I/O Points: It can support up to 64 I/O points.

Detailed content

- Function Features

- High – performance Processing: Equipped with a powerful multi – core processor and a large amount of RAM, it can handle multiple tasks simultaneously and quickly process a large amount of data, meeting the needs of complex control and automation applications.

- Redundant Design: It has a built – in redundancy function. Usually, two PM891 controllers can work as a pair of redundant controllers. When the main processor fails, it can quickly switch to the standby processor to ensure the high availability and reliability of the system.

- Rich Communication Capabilities: It supports a variety of communication protocols, such as Ethernet, Profibus, and Modbus, which can communicate with various I/O modules and other devices, enhancing the integration ability with other systems and devices.

- Advanced Diagnosis and Troubleshooting: It has advanced diagnosis and troubleshooting functions, including comprehensive event logging and a built – in web server for remote access and monitoring, which helps to quickly identify and solve potential problems and reduce downtime and maintenance costs.

- Compact and Easy to Integrate: It adopts a compact design, which is a monolithic unit integrating power supply, CPU board, and unit terminal, and can be easily integrated into a variety of control panels.

- Application Scenarios

- Process Industry: It is widely used in petroleum, chemical, electric power, metallurgy and other industries, and is used for the control and monitoring of production processes, such as the control of chemical reaction processes, the monitoring of power generation equipment, etc.

- Infrastructure: It can be applied to water treatment, sewage treatment and other projects, realizing the automatic control of water treatment processes, such as the control of water pump operation and the monitoring of water quality.

- Automobile Manufacturing: It is used in assembly lines, painting lines and other production links in automobile manufacturing plants, and is responsible for the control of equipment operation and the monitoring of process parameters to ensure the quality and production efficiency of automobile production.

- Food and Beverage Industry: It is used in the packaging and filling links of the food and beverage industry, and can accurately control the packaging and filling speed and quantity to ensure product quality and production efficiency.