Detailed content

1、 Technical specifications

Processor and Memory:

This module adopts high-performance processors and large capacity memory, which can quickly process various complex control algorithms and data exchange tasks, improving the system’s response speed and efficiency.

Equipped with 4GB DDR3-1333 SDRAM memory, supporting efficient data processing.

Communication interface:

Support multiple communication interfaces, such as Ethernet, serial communication, etc., to meet the needs of different users and achieve communication and data exchange with other devices or systems.

The system is equipped with six Ethernet ports for connecting the system to the network for communication with other devices or systems.

Power supply and voltage:

The power supply voltage is usually 28 V DC, with a voltage range of 18-32 VDC to ensure the normal operation of the system within this voltage range.

Two 24VDC power options are provided to supply power to the PLC itself or other external devices, increasing the flexibility and reliability of the system.

Storage capacity:

Supports 8K step flash EPROM program memory and 8K word data storage, capable of storing a large amount of program data and configuration information, ensuring system stability and reliability.

I/O configuration:

The standard configuration has 8 inputs and 6 outputs, but the I/O configuration is very flexible and can be expanded to a maximum of 142 I/O points to meet more complex application requirements.

Non volatile storage:

Equipped with NVSRAM (non-volatile static random access memory), it can store 3067 non-volatile program variables, 64 accumulators, and 338 forces, and retain its stored information even when the system is powered off.

2、 Functional Features

High speed processing capability:

The high-performance processor and large capacity memory ensure that the module can quickly handle complex control algorithms and data exchange tasks.

Multiple communication protocols supported:

Supports multiple communication protocols, including fieldbus communication protocols (such as Profibus, Modbus, DeviceNet, etc.) and Ethernet communication protocols (such as TCP/IP, EtherNet/IP, etc.), facilitating communication with different types of devices and systems.

Programmability:

Supports multiple programming languages such as C/C++, Ladder Logic, etc., allowing users to write custom control programs according to their own needs.

High reliability:

Using high-quality materials and manufacturing processes, it has high reliability and stability, and can meet the needs of various industrial applications.

Easy to maintain and debug:

It has self diagnostic function, which can detect and report faults, facilitate users to discover and solve problems in a timely manner, and reduce maintenance costs. At the same time, it also has the feature of easy debugging, allowing users to conveniently perform program debugging and system testing.

Strong scalability:

It can be combined and expanded with other modules, making it convenient for users to configure and upgrade the system according to their own needs.

Strong adaptability:

Capable of adapting to different industrial environments and working conditions, by configuring different parameters and protocols, it can meet different equipment and system requirements.

Safe and reliable:

We have adopted encryption technology and security protocols to ensure the security of data transmission. At the same time, it also has fault diagnosis and protection functions, which can timely alarm and take protective measures when faults occur.

3、 Application scenarios

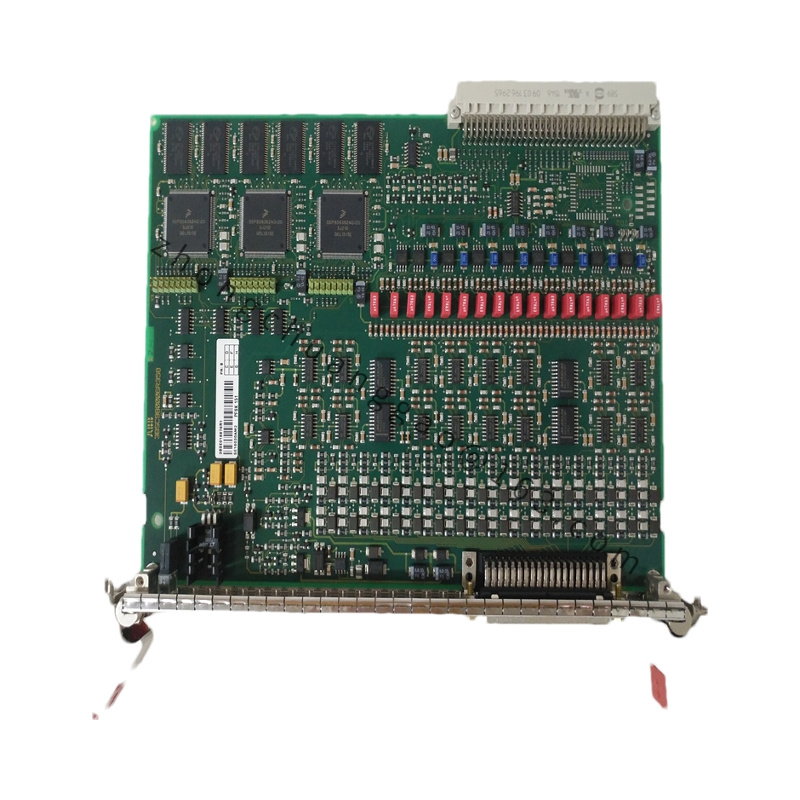

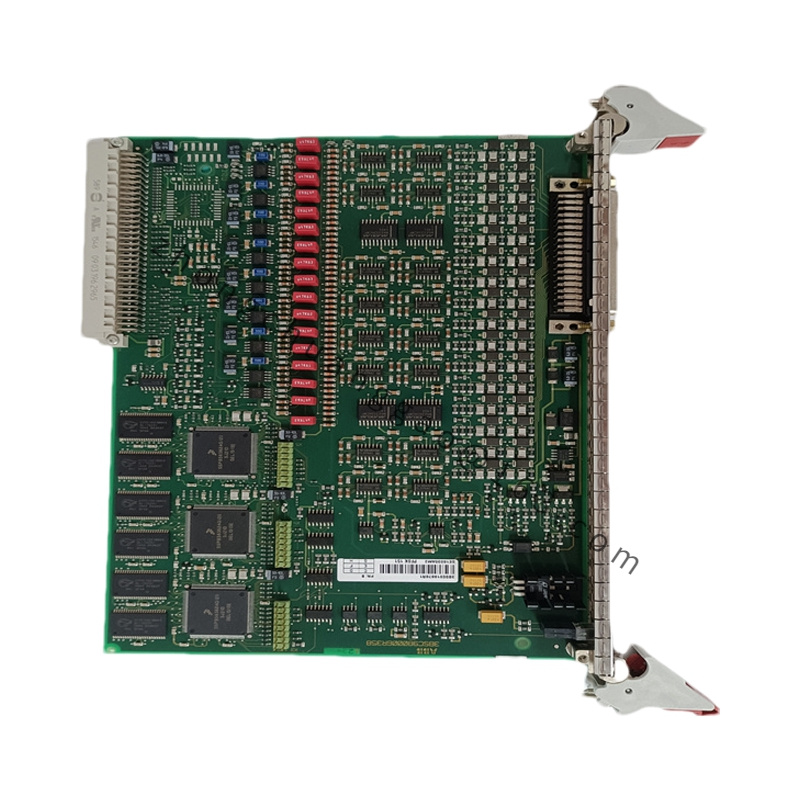

The ABB PFSK151 3BSE018876R1 communication module is widely used in the field of industrial automation and control systems, such as:

Manufacturing industry: used to achieve functions such as data collection, control, and monitoring, improve production efficiency, reduce operating costs, and enhance system reliability.

Power system: plays an important role in power control and monitoring systems to ensure the stable operation of the power system.

Chemical industry: Implementing automated control and monitoring in chemical processes to improve production efficiency and safety.

Water treatment: Automated control and monitoring are carried out in the water treatment system to ensure that water quality meets standards and the system operates stably.

Building automation: used for the automation control and monitoring of building equipment, such as air conditioning systems, lighting systems, etc.

.jpg)