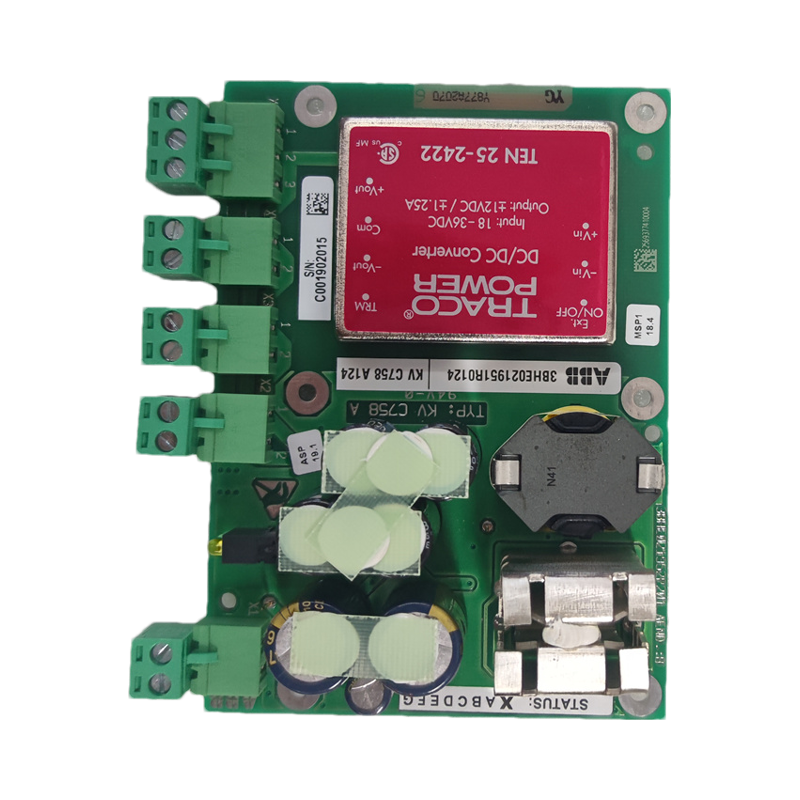

ABB KVC758A124 3BHE021951R1024

The ABB KVC758A124 and 3BHE021951R1024 are control modules designed for industrial automation and process control systems, particularly within ABB’s distributed control system (DCS) ecosystem. While the 3BHE021951R1024 is identified as a voltage subprint component for the KVC758A124 module 1, both devices share core functionalities and are often integrated in mission-critical applications. Below is a consolidated overview based on verified technical insights and industry context:

Detailed content

Technical Specifications

KVC758A124

- Power Supply:

- Operates on 24V DC with low power consumption, ensuring stable performance in industrial environments.

- Signal Handling:

- Supports analog and digital I/O signals (e.g., 4–20 mA, 0–10 V, discrete inputs/outputs) with isolated channels to prevent interference.

- Physical Design:

- DIN rail-mountable form factor for space-efficient installation in control cabinets.

- Lightweight construction for easy integration.

- Environmental Parameters:

- Temperature Range: -20°C to +60°C ambient, suitable for harsh conditions.

- Humidity: 5–95% non-condensing.

- Enclosure Rating: IP20 (standard) with optional ruggedized versions for dust/water resistance.

- Communication:

- Protocols: Modbus RTU, Profibus DP, and Ethernet for seamless integration with PLCs, HMIs, and higher-level systems.

- Redundancy: Dual-port Ethernet option for fault-tolerant communication.

3BHE021951R1024

- Role:

- Serves as a dual-voltage subprint for the KVC758A124 module, providing power regulation and signal conditioning for specific applications like the ACS 5000 water-cooled drive system 1.

- Technical Focus:

- Optimized for high-voltage input/output management in industrial drives.

- Integrates with the KVC758A124 to enhance voltage stability and system reliability.

Functional Features

- Multi-Channel I/O Capability:

- Both modules enable analog-to-digital conversion for sensor signals and discrete control for actuators, valves, and motors.

- Built-in signal conditioning (filtering, scaling) ensures accurate data acquisition.

- Diagnostic and Monitoring:

- Real-time health checks for signal integrity, power status, and temperature.

- Error reporting via LED indicators or digital outputs for predictive maintenance.

- Modular Architecture:

- Scalable configuration allows expansion via additional I/O modules.

- Hot-swap functionality minimizes downtime during module replacement.

- Safety Compliance:

- SIL2 certification for safety-critical applications (e.g., emergency shutdown systems).

- EMC immunity compliant with IEC 61000-6-2 standards.

Application Scenarios

- Industrial Automation:

- Manufacturing: Controls conveyor belts, pumps, and mixers in food processing, pharmaceuticals, and automotive assembly.

- Packaging: Optimizes filling/sealing processes with precise speed and pressure control.

- Power Generation:

- Combined Cycle Plants: Manages turbine speed, steam flow, and generator synchronization.

- Renewable Energy: Converts variable-speed generator outputs in wind farms to grid-compatible power.

- Oil and Gas:

- Refineries: Monitors pressure, temperature, and flow in distillation columns.

- Subsea Systems: Provides reliable control for subsea pumps and valves.

- Water and Wastewater:

- Treatment Plants: Regulates chemical dosing and sludge management.

- Pumping Stations: Ensures efficient water distribution via remote monitoring.

- HVAC Systems:

- Building Automation: Controls heating, ventilation, and air conditioning for energy efficiency.

Integration and Compatibility

- System Integration:

- Works with ABB’s Bailey INFI 90 controller for centralized process management.

- Compatible with third-party PLCs (e.g., Siemens S7, Rockwell ControlLogix) via standard protocols.

- Software Tools:

- Configured using ABB’s Control Builder M for parameter setup and firmware updates.

- Supports ABB Ability™ Condition Monitoring for remote diagnostics.

- Safety Functions:

- STO (Safe Torque Off) and SS1 (Safe Stop 1) for motor control.

- Failsafe design ensures predictable behavior during power loss or communication failure.

Environmental and Safety Considerations

- Sustainability:

- RoHS-compliant materials reduce environmental impact.

- Energy-efficient design aligns with EU ErP Directive requirements.

- Rugged Reliability:

- Resistant to vibration, shock, and voltage spikes.

- Optional conformal coating enhances durability in corrosive environments.

Discover our other products

MAGNETEK 1500MA 937-K-TC-P

MAGNETEK 400W H-33 1030-93

Magnetek 116 13-15-181100Rpm 208-230V

Magnetek Omega 500W Rk RK-M3-3J w 3-1J-S1053 48V, 10A ^

MagneTek 448 13-14-16- 277V- 1075RPM

.jpg)

.jpg)