ABB ICSE08B5

Technical Specifications

- Input Capabilities:

- 8-channel analog input module supporting -10 V to +10 V voltage signals 2.

- 12-bit resolution with ±0.5% full-scale accuracy, ensuring precise measurement of temperature, pressure, or flow parameters 2.

- Update rate of 250 ms per channel for real-time data acquisition 2.

Detailed content

- Signal Conditioning:

- Galvanic isolation (1500 V) protects against electrical noise and ground loops 2.

- Open-circuit detection and short-circuit protection enhance reliability in harsh environments 2.

- Power Requirements:

- Operates on 24 VDC ±10%, with a typical power consumption of 60 mA 2.

- Environmental Ratings:

- Operational temperature: -25°C to +70°C, suitable for extreme industrial conditions 2.

- Storage temperature: -40°C to +80°C, ensuring resilience during transportation 2.

- Protection class: IP20 (dust and solid particle protection) for indoor use 2.

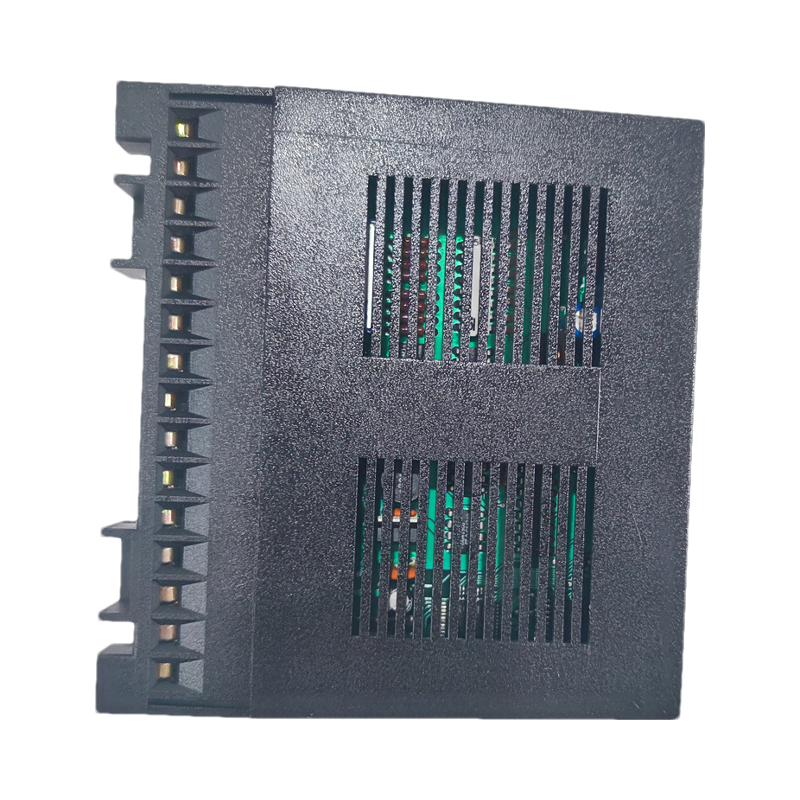

- Physical Design:

- Compact dimensions: 37 mm (width) × 26 mm (height) × 40 mm (depth), weighing 0.412 kg for space-efficient installation 2.

- DIN rail-mountable with modular connectivity for easy integration into existing systems 6.

Functional Features

- Communication Protocols:

- Supports RS-485, Modbus RTU, and CANopen for seamless integration with PLCs (e.g., ABB AC31) and third-party systems 210.

- Bidirectional data exchange enables remote configuration and diagnostics 2.

- Modular Integration:

- Hot-swap capability allows module replacement without system downtime 2.

- Compatible with ABB’s Procontic CS31 series for scalable automation solutions 10.

- Diagnostic Tools:

- Front-panel LED indicators for power status, fault detection, and channel health 2.

- Built-in self-test function identifies hardware malfunctions automatically 2.

- Safety Compliance:

- CE-marked for EMC and low voltage directives, ensuring compliance with EU standards 9.

- RoHS-compliant materials minimize environmental impact 11.

Application Scenarios

- Industrial Process Control:

- Monitors temperature and pressure in chemical reactors, distillation columns, and pharmaceutical sterilization systems 26.

- Integrates with PLCs to adjust process parameters in real time, ensuring quality control 10.

- Energy Management:

- Measures flow rates in oil and gas pipelines, optimizing energy distribution and reducing waste 6.

- Supports renewable energy installations by monitoring solar panel efficiency and wind turbine performance 2.

- Building Automation:

- Manages HVAC systems in commercial buildings, balancing comfort and energy efficiency 2.

- Controls lighting and ventilation based on occupancy sensors or environmental data 6.

- Manufacturing:

- Collects data from production lines to detect anomalies and prevent equipment failures 2.

- Enables predictive maintenance by analyzing sensor trends in automotive or electronics assembly 6.

Compatibility and Certifications

- System Integration:

- Works with ABB’s Automation Builder software for configuration and programming 7.

- Supports IEC 61131-3 programming languages (Ladder Logic, Function Block Diagram) 7.

- Certifications:

- CE, RoHS, and REACH compliance ensure adherence to global environmental and safety standards 11.

- CSA-certified for non-hazardous locations in North America 9.

Operational Benefits

- Reliability:

- Long MTBF (mean time between failures) of 150,000 hours and short MTTR (mean time to repair) of 30 minutes minimize downtime 2.

- Redundant power supply options enhance fault tolerance in critical applications 6.

- Energy Efficiency:

- Low power consumption design reduces operational costs in energy-intensive environments 2.

- Scalability:

- Parallel configurations allow expansion to handle large-scale data acquisition requirements 6.

Limitations in Available Data

While the ICSE08B5’s core specifications and functionalities are well-documented, certain details—such as exact thermal performance curves for extreme environments or compatibility with non-ABB SCADA systems—may require direct consultation with ABB’s technical documentation. For mission-critical applications, verifying integration with existing infrastructure and obtaining certified performance data is recommended.

Discover our other products

Moore Siemens Procidia 16357-101 iO-8DI24DMN 8-Ch. DI Non Isolated 24Vdc 16357-101

SIEMENS MOORE ASSY NO PN: 15733-1 INPUT MODULE DISCRETE PC BOARD 15733-1

SIEMENS MOORE APACS+ QUADLOG OVERVOLTAGE DEVICE – 39PSR6ORIGINAL 39PSR6ORIGINAL

SIEMENS MOORE APACS + BDM TRANSITION BOARD – 16256-111 16256-111

SIEMENS 91-HF / 91HF 91-HF

SIEMENS 372A11NN / 372A11NN 372A11NN

SIEMENS MOORE 16289-200 SIXRAC SIX SLOT MODULE RACK 16289-200

Siemens Moore Redundancy Cable 16137-188 16137-188

Siemens Moore Redundancy Cable 16137-189 16137-189

Moore Siemens 16357-116 Procidia iO-4RT 4 Channel RTD Input – 16357-116

Moore / Siemens 173S-M64 Pneumatic Pressure Transmitter NSN 6685-01-221-41 10 173S-M64

Moore Siemens Procidia 16357-101 iO-8DI24DMN 8-Ch. DI Non Isolated 24Vdc 16357-101

SIEMENS MOORE ASSY NO PN: 15733-1 INPUT MODULE DISCRETE PC BOARD 15733-1

SIEMENS MOORE APACS+ QUADLOG OVERVOLTAGE DEVICE – 39PSR6ORIGINAL 39PSR6ORIGINAL

SIEMENS MOORE APACS + BDM TRANSITION BOARD – 16256-111 16256-111

SIEMENS 91-HF / 91HF 91-HF

SIEMENS 372A11NN / 372A11NN 372A11NN

SIEMENS MOORE 16289-200 SIXRAC SIX SLOT MODULE RACK 16289-200

Siemens Moore Redundancy Cable 16137-188 16137-188

Siemens Moore Redundancy Cable 16137-189 16137-189

Moore Siemens 16357-116 Procidia iO-4RT 4 Channel RTD Input – 16357-116

Moore / Siemens 173S-M64 Pneumatic Pressure Transmitter NSN 6685-01-221-41 10 173S-M64

.jpg)