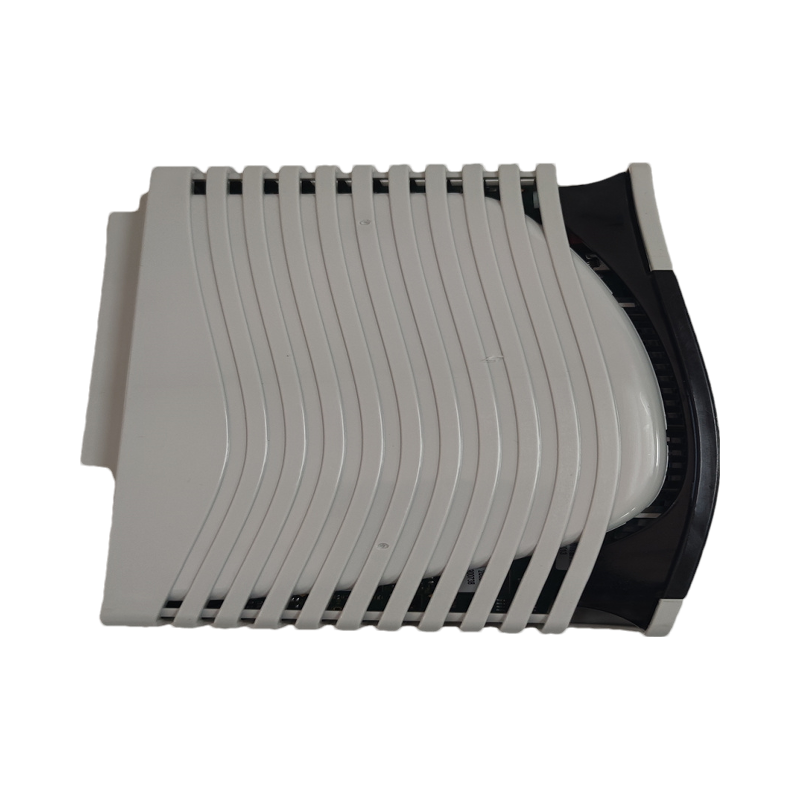

ABB AO02

Technical Specifications

- Output Capabilities:

- 16 independently configurable channels supporting 4–20 mA (current mode) or 1–5 VDC (voltage mode) signals 111.

- Each channel features a dedicated 12-bit D/A converter, providing high resolution for accurate signal reproduction.

- Output accuracy: ±0.01% of full-scale range (FSR = 25 mA or 6.25 VDC), ensuring minimal error in critical applications 111.

Detailed content

- Signal Conditioning:

- Galvanic isolation (1500 V for 1 minute) protects against electrical noise and ground loops 111.

- Open-circuit detection within 5 seconds and short-circuit protection (max 26 mA in current mode) enhance system reliability 111.

- Power Requirements:

- Module power: 24 VDC ±10%, with typical consumption of 100 mA and maximum 125 mA 111.

- Field IO power: 20 mA/channel @ 24 VDC ±10% 111.

- Environmental Ratings:

- Operational temperature: -40°C to +70°C, suitable for extreme industrial conditions 111.

- Storage temperature: -40°C to +85°C, ensuring resilience during transportation 111.

- Protection class: IP20 (dust and solid particle protection) for indoor use 111.

- Physical Design:

- Compact DIN rail-mountable form factor (190 mm standard height) for space-efficient installation 111.

- Horizontal or vertical mounting compatibility with ABB’s XBS 01-EPD base for field power distribution 12.

Functional Features

- HART Communication:

- Supports HART v5.4 protocol for bidirectional communication with intelligent field devices, enabling remote configuration and diagnostics 111.

- Up to 20 secondary HART variables (4 per channel) with update rates as fast as 2.5 seconds 111.

- Modular Integration:

- Hot-swap capability allows module replacement without system downtime 111.

- Compatible with ABB’s SD Series I/O and Symphony Plus DCS, ensuring seamless integration with existing infrastructure 111.

- Diagnostic Tools:

- Front-panel LED indicators for power status, fault detection, and individual channel health 111.

- Mini USB port for local diagnostics and firmware updates 111.

- Remote diagnostics via Symphony Plus system for centralized monitoring 111.

- Safety Compliance:

- CE-marked for EMC and low voltage directives, UL-listed for North American markets 111.

- CSA-certified for non-hazardous and Class I, Division 2 hazardous locations (via RAO02 redundant variant) 15.

Application Scenarios

- Industrial Process Control:

- Regulates valve positions in chemical reactors, distillation columns, and pharmaceutical sterilization systems to maintain process stability 111.

- Integrates with PLCs (e.g., ABB AC800M) to adjust heating/cooling systems in real time.

- Power Generation:

- Controls steam turbine inlet valves and generator excitation systems in thermal power plants 111.

- Supports renewable energy installations by managing solar panel tracking systems and wind turbine pitch controls.

- HVAC and Building Automation:

- Manages variable air volume (VAV) systems and chilled water pumps in commercial buildings, optimizing energy efficiency 111.

- Oil and Gas:

- Controls flow rates in pipelines and refinery processes, ensuring compliance with safety and environmental standards 111.

- Food and Beverage:

- Maintains precise temperature and pressure in pasteurization and fermentation processes to ensure product quality 111.

Compatibility and Certifications

- System Integration:

- Works seamlessly with ABB’s Automation Builder software for configuration and programming 111.

- Supports IEC 61131-3 programming languages (Ladder Logic, Function Block Diagram).

- Communication Protocols:

- Integrates with fieldbus systems (e.g., Profibus DP, Modbus RTU) via ABB’s communication modules 111.

- Compatible with third-party SCADA systems for data aggregation and remote monitoring.

- Certifications:

- CE, UL, and CSA (non-hazardous locations) certifications ensure compliance with global standards 11115.

Operational Benefits

- Reliability:

- Redundant power supply options and error-correcting memory enhance fault tolerance 111.

- Long MTBF (95,637 hours) and short MTTR (1 hour) minimize downtime 2.

- Energy Efficiency:

- Low power consumption design reduces operational costs in energy-intensive applications 111.

- Scalability:

- Parallel configurations allow expansion to handle large-scale control requirements 111.

Limitations in Available Data

While the AO02’s core specifications and functionalities are well-documented, certain details—such as exact thermal performance curves for extreme environments or compatibility with non-ABB systems—may require direct consultation with ABB’s technical documentation. For mission-critical applications, verifying integration with existing infrastructure and obtaining certified performance data is recommended.

Discover our other products

SIEMENS MOORE APACS+ QUADLOG PACK WITH 8 LOAD ADAPTER 125VDC – 16414-82 16414-82

SIEMENS MOORE APACS+ QUADLOG PACK WITH 8 LOAD ADAPTER 24VDC – 16414-62 16414-62

SIEMENS MOORE APACS+ QUADLOG PACK WITH 8 LOAD ADAPTER 48-60VDC – 16414-72 16414-72

SIEMENS Moore Link Interface Module Termination Strip 16113-1-2. 16113-1-2

SIEMENS Moore MBX Termination Strip 16176-1-0C 16176-1-0C

Siemens Moore MBI Cable 16137-174 16137-174

15733414 SIEMENS MOORE 15733-41-4 INPUT MODULE DISCRETE PC BOARD FREESHIPSAMEDA Y 15733-41-4

SIEMENS 372-A11NF / 372A11NF 372-A11NF

SIEMENS 14870-5S3 / 148705S3 14870-5S3

Siemens Moore MBUS Cable 16137-153 – NIB 16137-153-NIB

SIEMENS MOORE APACS+ QUADLOG PACK WITH 8 LOAD ADAPTER 125VDC – 16414-82 16414-82

SIEMENS MOORE APACS+ QUADLOG PACK WITH 8 LOAD ADAPTER 24VDC – 16414-62 16414-62

SIEMENS MOORE APACS+ QUADLOG PACK WITH 8 LOAD ADAPTER 48-60VDC – 16414-72 16414-72

SIEMENS Moore Link Interface Module Termination Strip 16113-1-2. 16113-1-2

SIEMENS Moore MBX Termination Strip 16176-1-0C 16176-1-0C

Siemens Moore MBI Cable 16137-174 16137-174

15733414 SIEMENS MOORE 15733-41-4 INPUT MODULE DISCRETE PC BOARD FREESHIPSAMEDA Y 15733-41-4

SIEMENS 372-A11NF / 372A11NF 372-A11NF

SIEMENS 14870-5S3 / 148705S3 14870-5S3

Siemens Moore MBUS Cable 16137-153 – NIB 16137-153-NIB