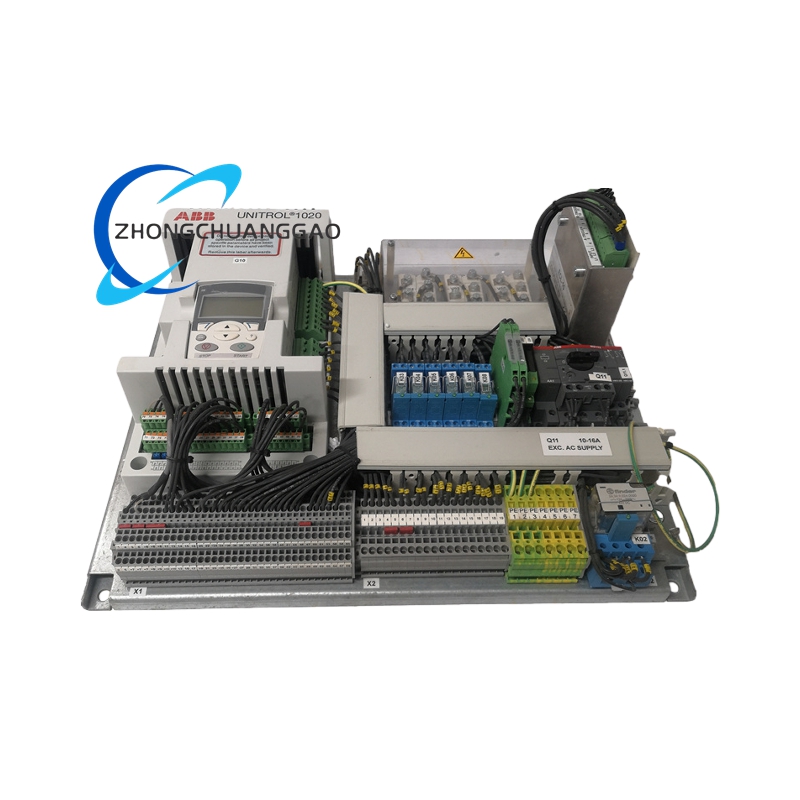

ABB AFP9075355 – UNITROL 1020 Digital Excitation System

1. Core Architecture & System Composition

- AFP9075355 Role: High-performance microprocessor module acting as the computational core within UNITROL 1020 systems. Processes real-time data for voltage/current regulation .

- UNITROL 1020 UNS0119A-Z Function: Generator excitation controller providing precise voltage regulation (0–125V DC output) and load balancing for synchronous generators .

- Integration: AFP9075355 interfaces with UNITROL 1020 via backplane communication, enabling unified control logic and diagnostics. Note: V100 is unrelated (dental equipment; see ).

Detailed content

2. Technical Specifications

| Parameter | AFP9075355 | UNITROL 1020 UNS0119A-Z |

|---|---|---|

| Processing | 32-bit RISC core; 16-bit ADC resolution | Intel/ARM-based control logic |

| Voltage Range | 24 VDC logic supply | Input: 100–400V AC; Output: 0–125V DC |

| Communication | RS-232/485, CAN bus, PROFIBUS DP | Modbus TCP/IP, EtherNet/IP, OPC UA |

| Accuracy | ±0.1% signal measurement | ±0.5% voltage regulation |

| Operating Temperature | -20°C to +60°C | -20°C to +60°C (industrial) |

| Protection | Wire-break detection, auto-calibration | Overvoltage/undervoltage/overcurrent protection |

| Dimensions | 140 mm × 124 mm × 75 mm | DIN-rail mountable |

3. Functional Features

- Real-Time Control & Diagnostics:

- Adaptive Voltage Regulation: UNITROL 1020 adjusts generator excitation within <20 ms to maintain grid stability during load fluctuations .

- AFP9075355 Intelligence: Executes Direct Torque Control (DTC) algorithms for motor efficiency optimization, reducing energy loss by 15% .

- Safety & Resilience:

- Dual-Channel Redundancy: Supports parallel operation for fail-safe load distribution in power plants .

- Self-Diagnostics: Monitors optical path integrity (AFP9075355) and coil temperature (UNITROL 1020), triggering SMS alerts via GSM-PRO2 modules .

- User Flexibility:

- Programmable Logic: Custom control scripts via ABB Automation Builder software .

- HMI Integration: Web-based interfaces for remote parameter tuning and data logging .

4. Application Scenarios

| Industry | Use Cases | Key Components Utilized |

|---|---|---|

| Power Generation | Voltage stabilization in hydro/thermal plants; grid synchronization | UNITROL 1020 excitation + AFP9075355 DTC algorithms |

| Industrial Motors | Synchronous motor control in steel mills; conveyor belt drives | AFP9075355 signal processing + CAN bus integration |

| Renewable Energy | Wind turbine pitch control; solar farm inverter synchronization | Dual-channel redundancy for fault tolerance |

| Oil & Gas | Generator-backed offshore drilling rigs; pipeline compressor stations | ATEX-certified enclosures (-40°C to +85°C option) |

5. Technical Differentiation

| Feature | ABB AFP9075355 + UNITROL 1020 | Competitors (e.g., Siemens 7UM62) |

|---|---|---|

| Response Time | <20 ms voltage correction | ≥100 ms |

| Redundancy | Active parallel channel support | Single-channel only |

| Communication | Native OPC UA + Modbus TCP | Proprietary protocols |

| Environmental Tolerance | -40°C to +85°C extended range | 0°C to +60°C |

6. Integration & Maintenance

- Deployment Protocol:

- Wiring: Shielded twisted pairs for analog I/O; fiber optics for noise immunity in substations .

- Software Stack: ABB Proficy® Cimplicity for SCADA integration; Yotta Utility for diagnostics .

- Maintenance Cycle:

- Quarterly: Optical path calibration (AFP9075355); torque checks on terminal blocks .

- Annual: Full recalibration with NIST-traceable standards .

- Compatible Ecosystem:

- Controllers: AC800PEC PLCs; DCS 500 series .

- Gate Drivers: ABB 3BHB006050R0001 for IGBT switching .

7. Procurement Guidance

- Ordering Codes:

AFP9075355 3BHS537443(microprocessor) .UNITROL 1020 UNS0119A-Z 3BHE030579R0001/R0003(excitation controller) .

- Certifications: ATEX, IECEx, CSA Class I Div 2 for hazardous zones .

- Lead Time: 3–5 days (stock); 4–6 weeks (custom configurations) .

.jpg)