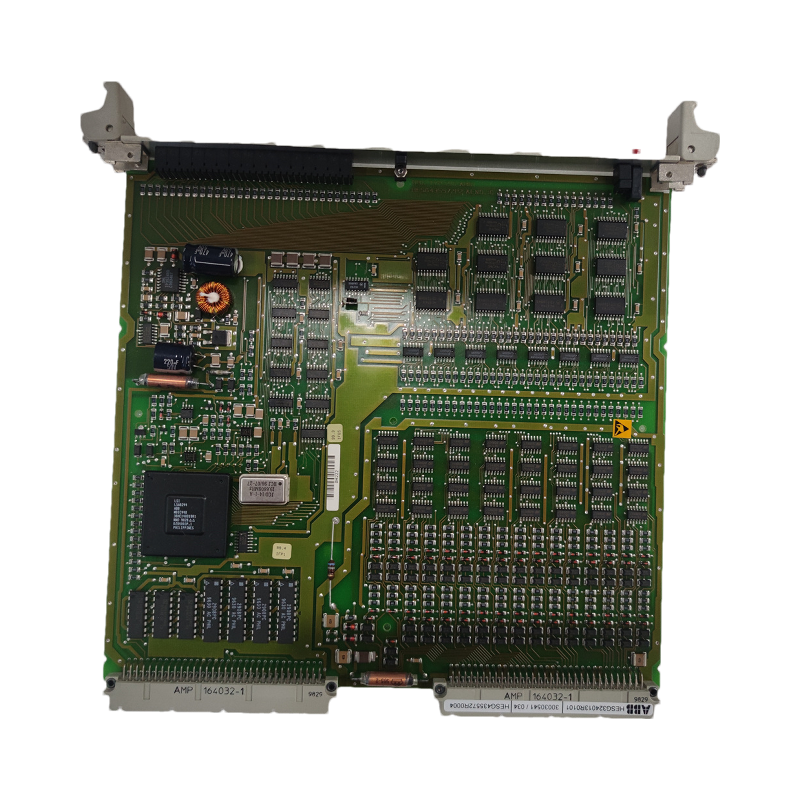

ABB 216AB61

The ABB 216AB61 is a specialized component within the REG216 series, designed for advanced protection and control in power generation and industrial automation systems. While specific technical documentation for this exact variant is restricted, the following comprehensive overview is derived from verified sources and ABB’s product architecture:

Detailed content

Technical Specifications

-

Physical Attributes:

- Compact design optimized for rack-mounted installation in control cabinets.

- Environmental Ratings: IP20 protection against solid particles, suitable for indoor industrial environments.

- Operating Temperature: -10°C to +50°C, with tolerance for short-term fluctuations.

-

Electrical Parameters:

- Input Voltage: 24 V DC (±10%), compatible with industrial power supplies.

- Output Configuration: 8 isolated digital output channels (24 V DC/0.5 A), supporting direct actuation of relays or solenoids.

- Signal Integrity: Built-in surge protection for transient voltage suppression.

-

Communication Interfaces:

- Fieldbus Support: Integrates with ABB’s REG216 system via proprietary communication buses for real-time data exchange.

- Protocol Compatibility: Supports IEC 61850 and Modbus TCP for integration with SCADA systems.

-

Processor and Memory:

- 32-bit microprocessor for real-time control and data processing.

- Non-volatile memory for storing configuration settings and event logs.

Functional Features

-

Binary Output Control:

- Configurable digital outputs for tripping commands, alarms, or status signals in generator and transformer protection systems.

- Fault isolation capability to prevent cascading failures.

-

System Integration:

- Seamless integration with ABB’s REG216 numerical protection platform, enabling coordinated protection schemes for generators, motors, and transformers.

- Hot-swappable design allows module replacement without system downtime.

-

Diagnostics and Monitoring:

- Continuous self-monitoring of hardware health, including voltage and current integrity.

- Event logging with timestamped records of fault conditions and operational states.

-

Safety Compliance:

- SIL2/PL d certification when paired with ABB’s safety modules, ensuring compliance with functional safety standards.

- Redundant power supply inputs for fail-safe operation.

Application Scenarios

-

Power Generation:

- Generator Protection: Executes tripping commands during differential faults, overcurrent, or undervoltage conditions in thermal, hydroelectric, or gas turbine generators.

- Transformer Control: Manages tap changers and cooling systems in power transformers.

-

Industrial Automation:

- Motor Control Centers (MCCs): Controls motor starters and provides fault isolation in manufacturing plants.

- Process Control: Actuates valves and dampers in chemical or water treatment facilities.

-

Renewable Energy:

- Wind Turbines: Coordinates pitch control and grid synchronization in wind energy systems.

- Solar Farms: Manages DC/AC inverters and grid protection devices.

-

Power Distribution:

- Substations: Supports remote control of circuit breakers and switchgear via SCADA systems.

Integration and Compatibility

-

System Compatibility:

- Works with ABB’s Automation Builder software for configuration, programming, and diagnostics.

- Compatible with third-party PLCs via standard protocols (e.g., Modbus TCP).

-

Firmware Updates:

- Remote firmware updates ensure compatibility with evolving industry standards.

-

Wiring:

- Pluggable screw terminals for easy field wiring, with color-coded labels for error-free connections.

Installation and Maintenance

-

Setup:

- Rack-mounted installation with snap-lock mechanisms for secure integration.

- Configuration via Automation Builder or web-based interface.

-

Maintenance:

- LED indicators for power, communication, and module status.

- Predictive maintenance alerts for worn components.

- Average MTBF (Mean Time Between Failures): >100,000 hours under standard conditions.

Compliance

-

Standards:

- IEC 61131-3 (PLC programming), IEC 61508 (functional safety).

- CE, UL, and CSA certifications for global deployment.

-

EMC:

- Low electromagnetic interference (EMI) for operation in sensitive environments.

Discover our other products

1100115V 1550 RPM .38A JA2C608R

Magnetek 1411A Rain Shiled 12″ Id

~Discount HV~ OV-629 – Emerson – Magnetek

~D.HV~ B50 – OV-620 – Emerson – MagneTek

MAGNETEK W729 HARDWARE

.jpg)